Squeeze service

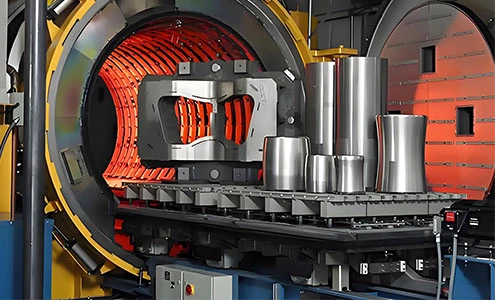

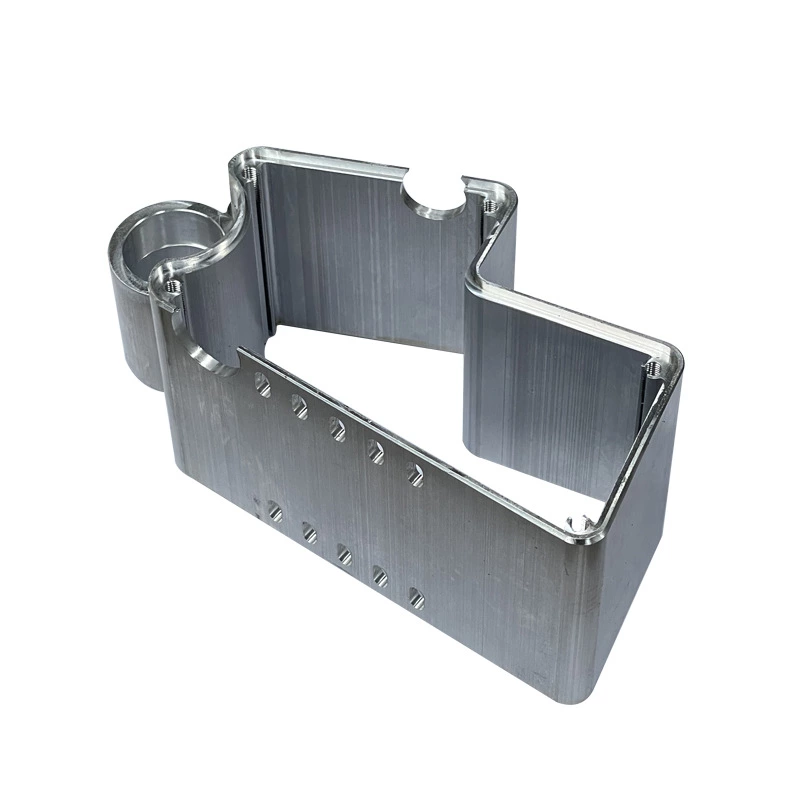

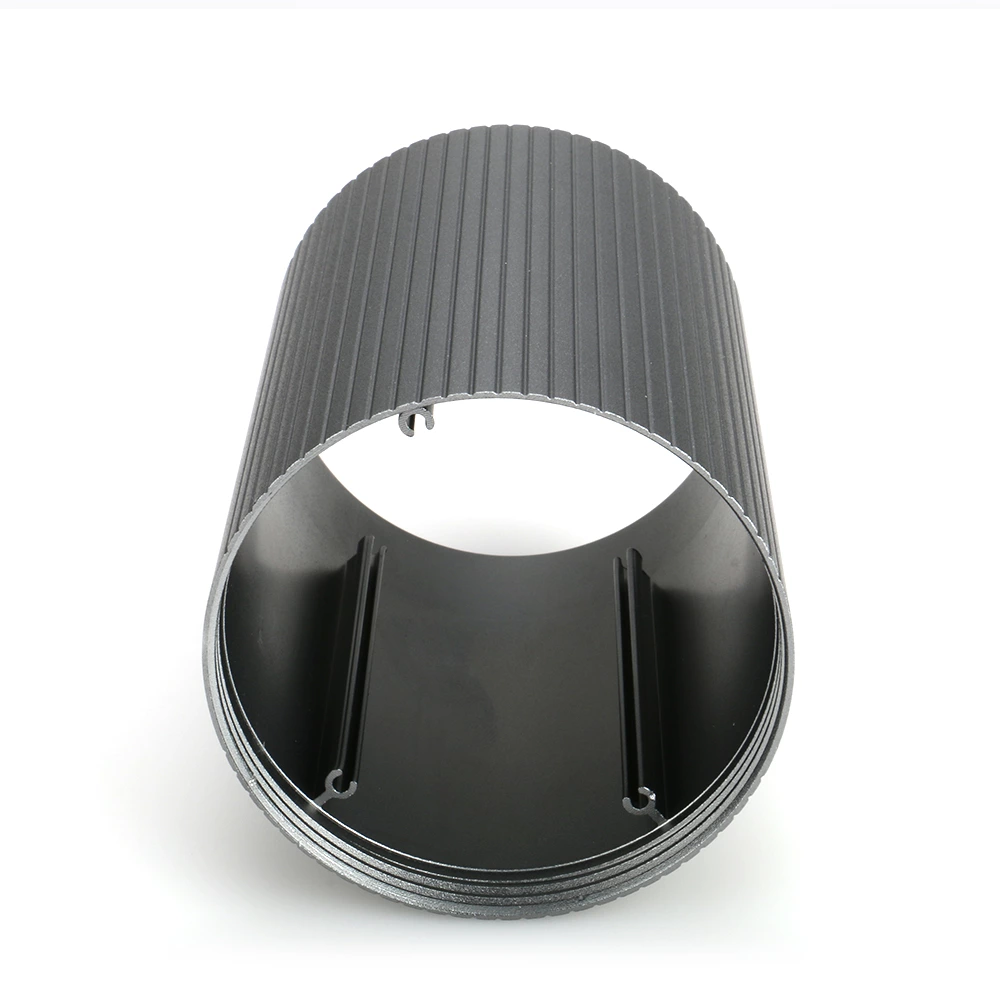

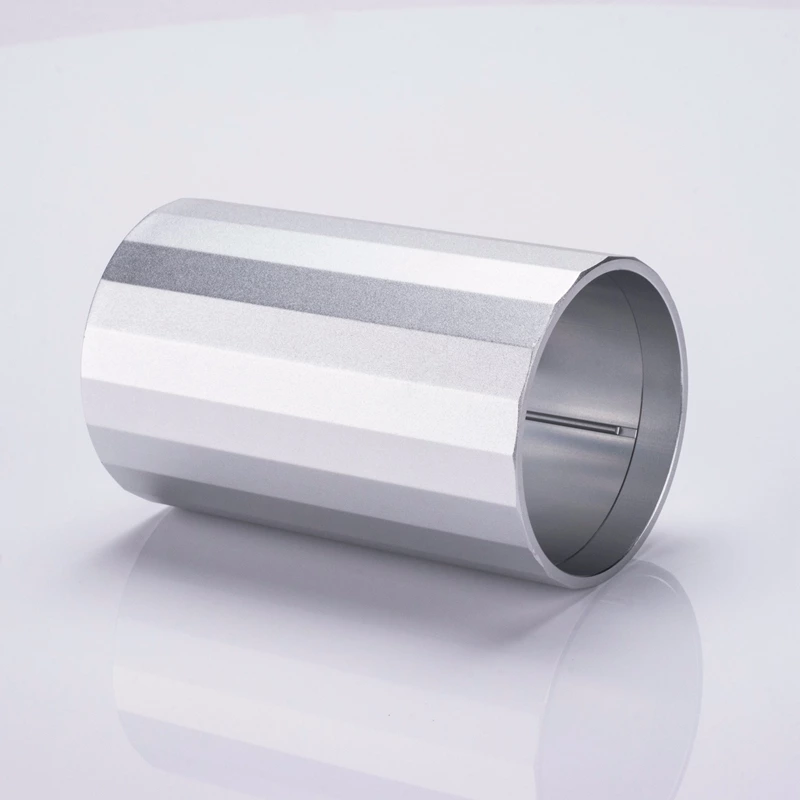

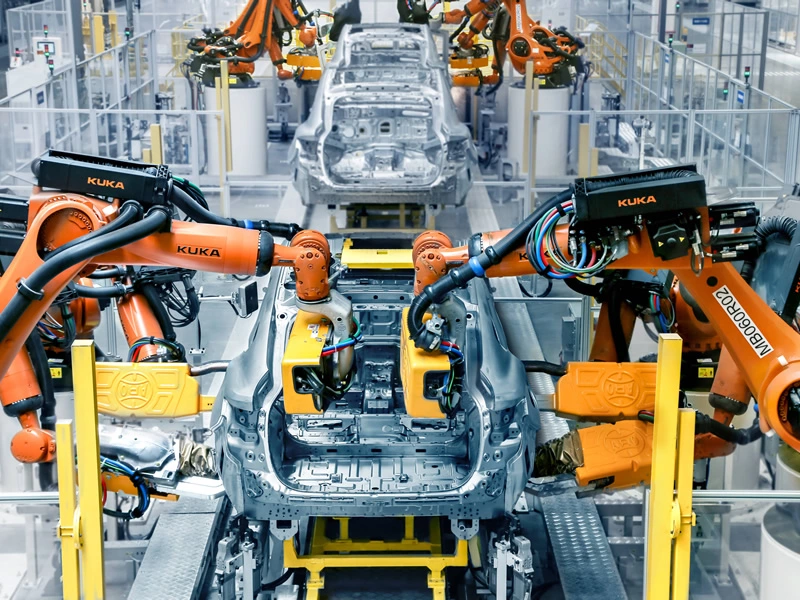

High-density metal parts, enhanced strength

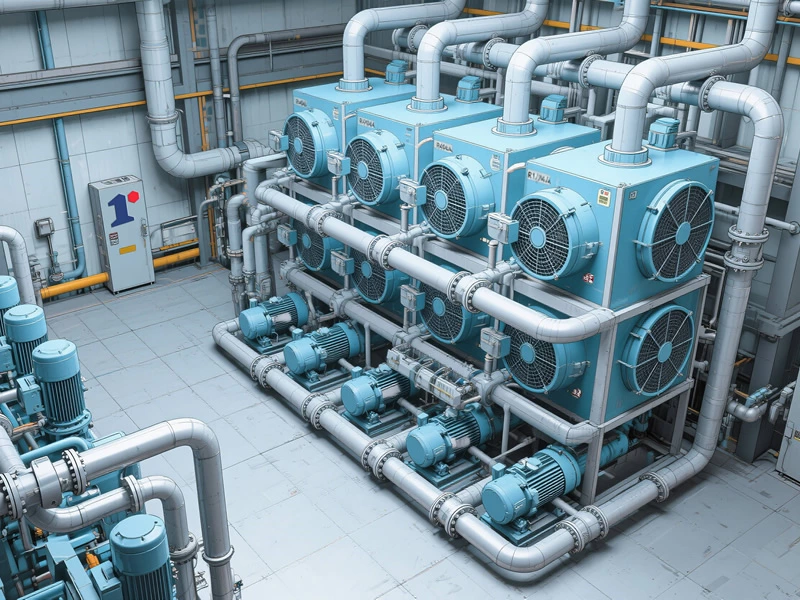

- SERVICES Our team will provide comprehensive support for your project, from process selection to final inspection, through professional technical coordination.

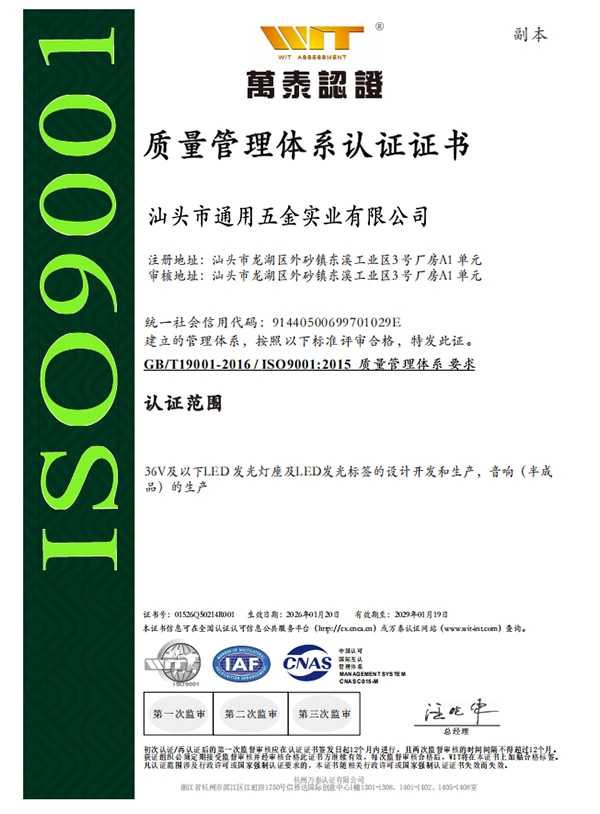

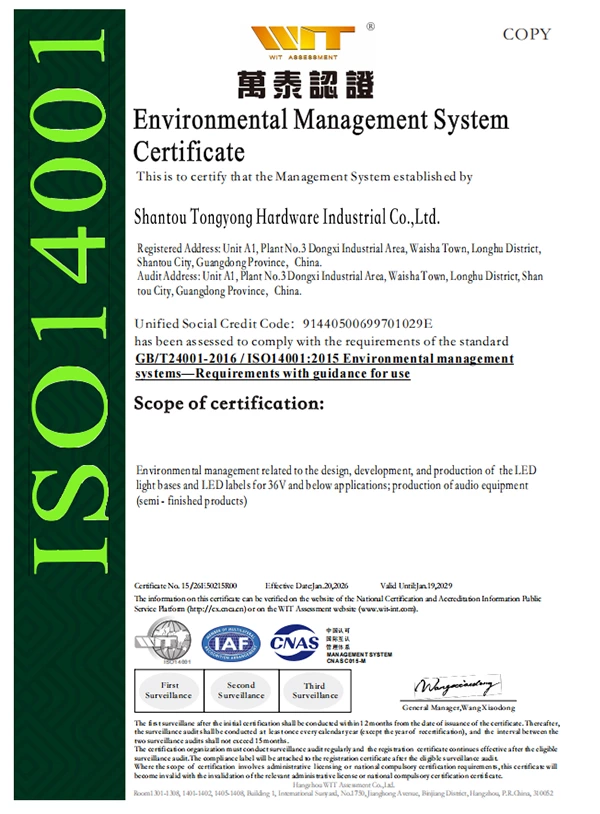

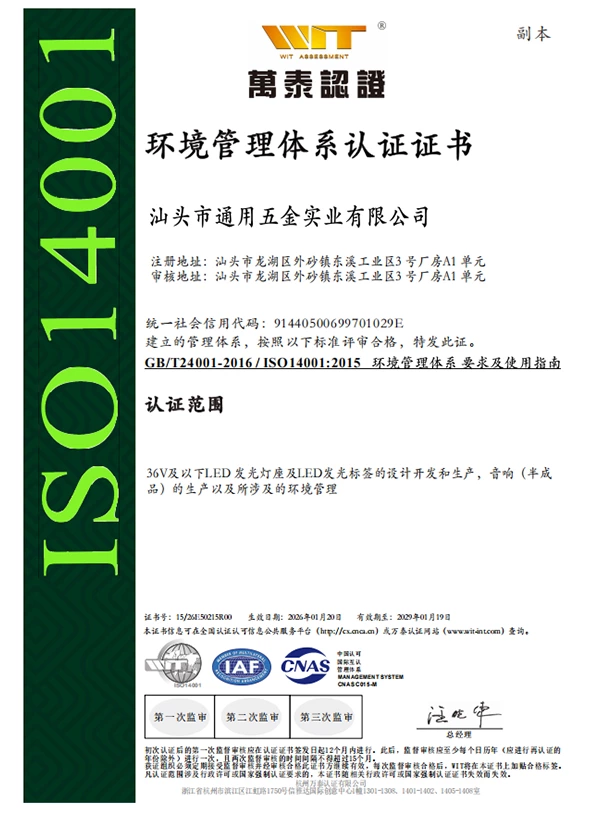

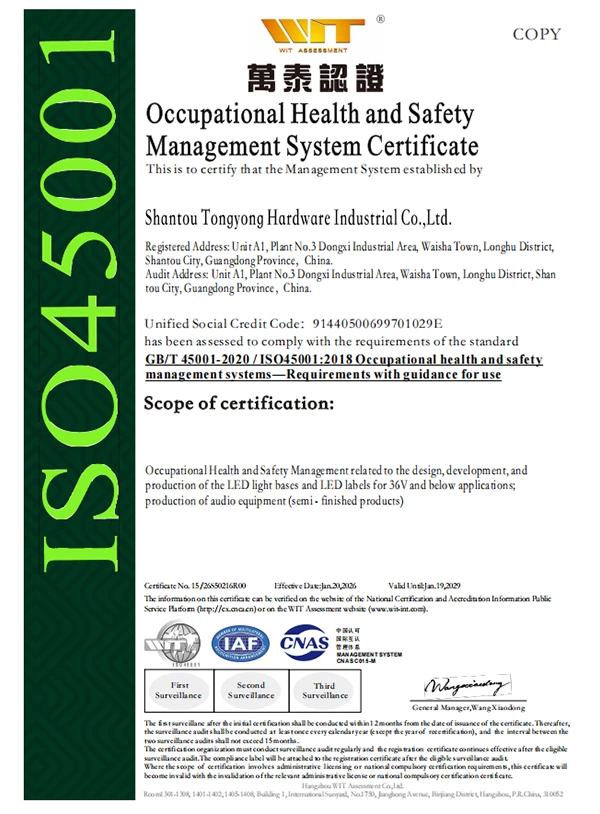

- Quality control pressure solidification can reduce porosity and improve internal structure, thereby ensuring reliable part quality.

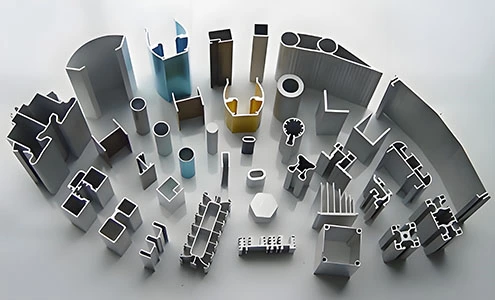

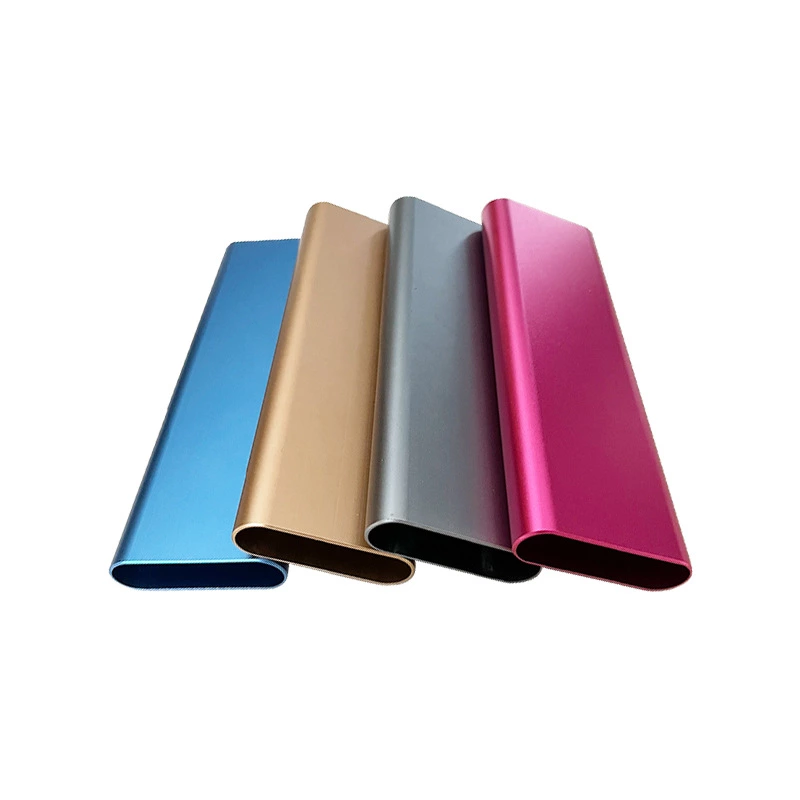

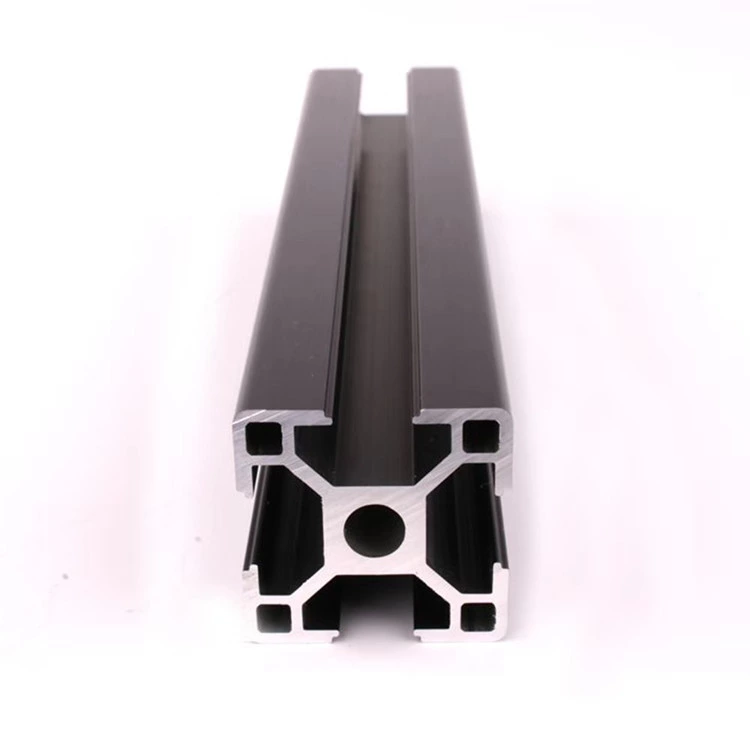

- CRUCIAL functional characteristics maintain precise dimensions and allow for secondary processing if necessary.

- Speed integrated casting and machining workflows enable faster turnaround times than traditional casting methods.

Jie Chen

buyer