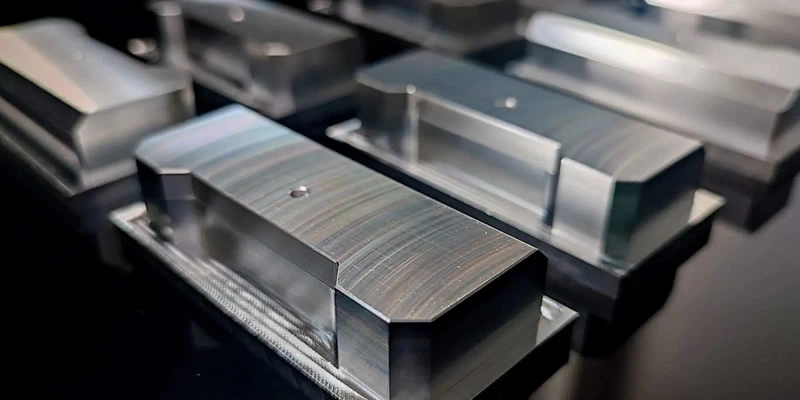

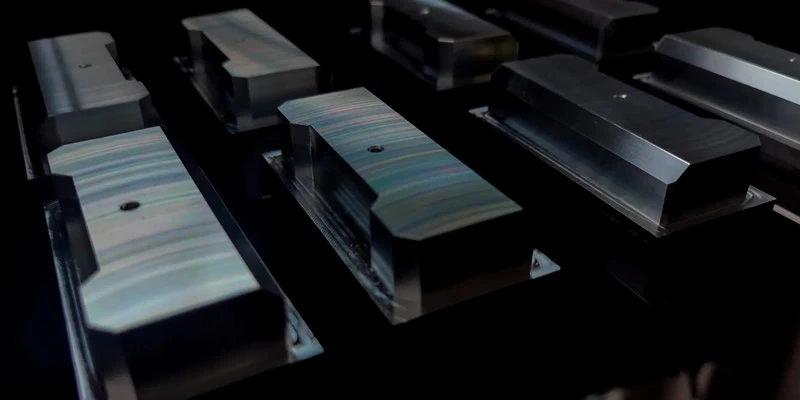

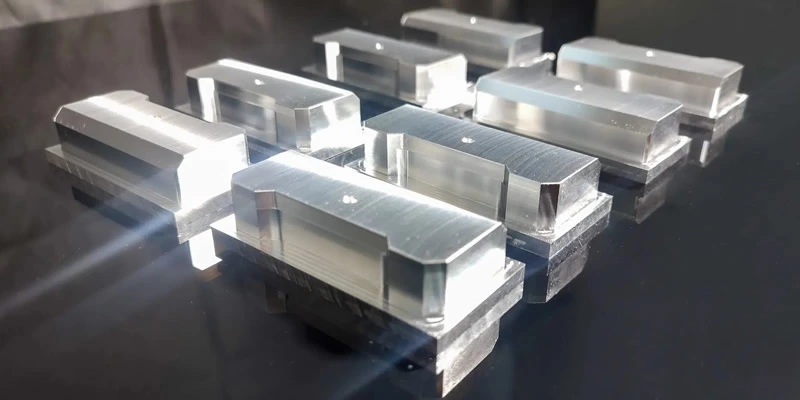

Shantou Tongyong Hardware Industry Co., Ltd. is a professional enterprise engaged in CNC machining, metal processing, and custom parts manufacturing. With over twenty years of experience in precision engineering, we have established a solid foundation in technological innovation, process control, and large-scale production. The company is equipped with various precision machining equipment and automated production lines, and has established a comprehensive process system and quality inspection capabilities to ensure that every product possesses superior precision and stability.

We uphold the core values of "honoring contracts, seeking truth from facts, strict execution, and pursuing excellence," and insist on being customer-centric, winning long-term cooperation through professionalism and integrity. With the business philosophy of "global collaborative innovation," we are committed to exploring innovation and solving complex manufacturing challenges with global customers, achieving mutual benefit and win-win results, and growing together.

We possess diversified manufacturing and design service capabilities, covering CNC machining, metal injection molding (MIM), sheet metal processing, die casting, etching, as well as optimized design and customized product development, providing one-stop, efficient and flexible production solutions for multiple industries.

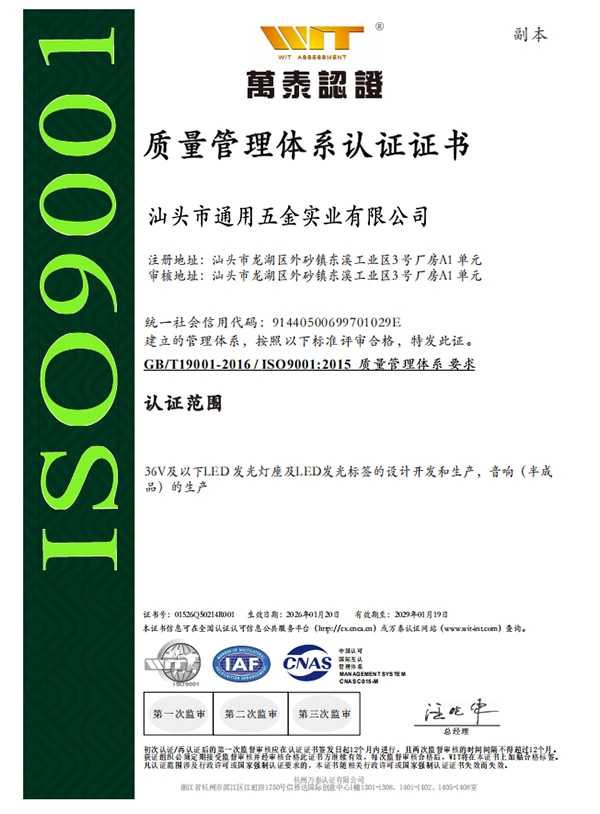

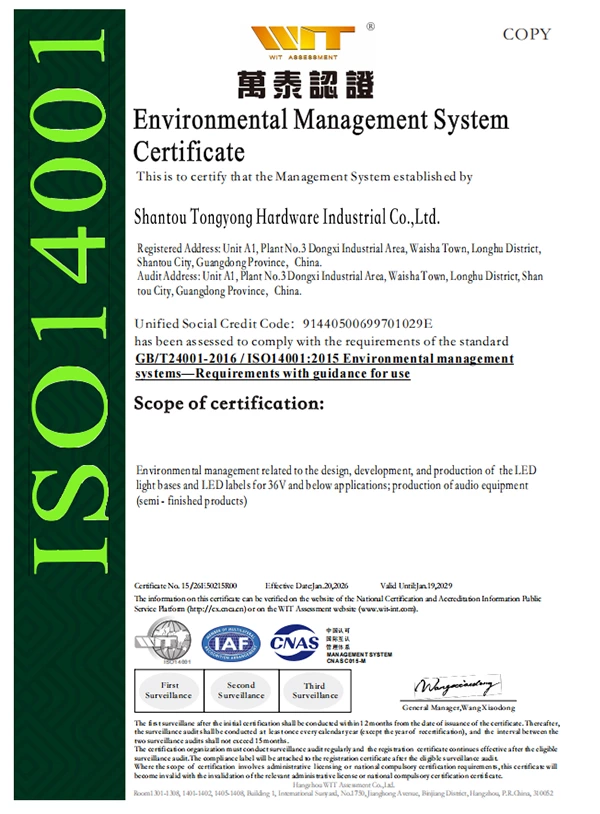

We strictly adhere to international management system standards and have obtained ISO 9001 Quality Management System, ISO 14001 Environmental Management System, and ISO 45001 Occupational Health and Safety Management System certifications, ensuring a standardized, efficient, and safe production process. Our products can be customized to meet various international standards and certifications, including but not limited to FDA, CE, UKCA, RoHS, REACH, JIS, UL, and FCC, providing fully compliant custom parts to global customers.

Leveraging our vertically integrated production system, we offer complete OEM/ODM services—from engineering design, rapid prototyping, precision machining to surface treatment, assembly, and global delivery. With advanced equipment, an experienced technical team, and an efficient service system, General Hardware helps global brands accelerate product development, improve performance, and maintain a leading edge in a highly competitive market.

As the company's core business segment, General Hardware, together with its subsidiary TOPFIRE Electronics Division, constitutes the company's comprehensive manufacturing capabilities. TOPFIRE Electronics Division focuses on customized solutions for electronic products and possesses independent R&D, production systems, and an official website. For more information on its capabilities, please visit its independent website ,www.topfire.net