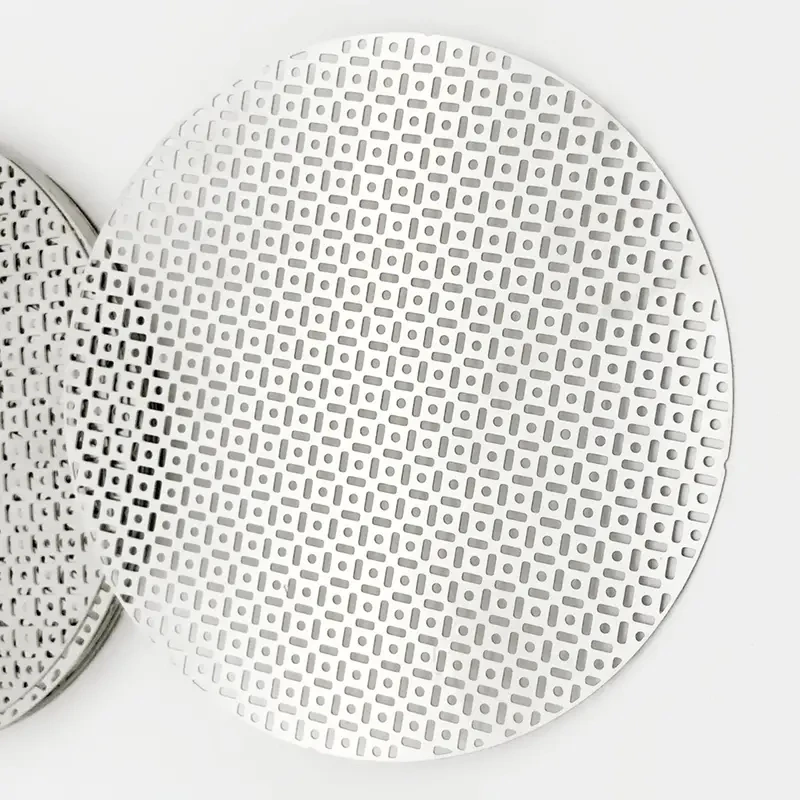

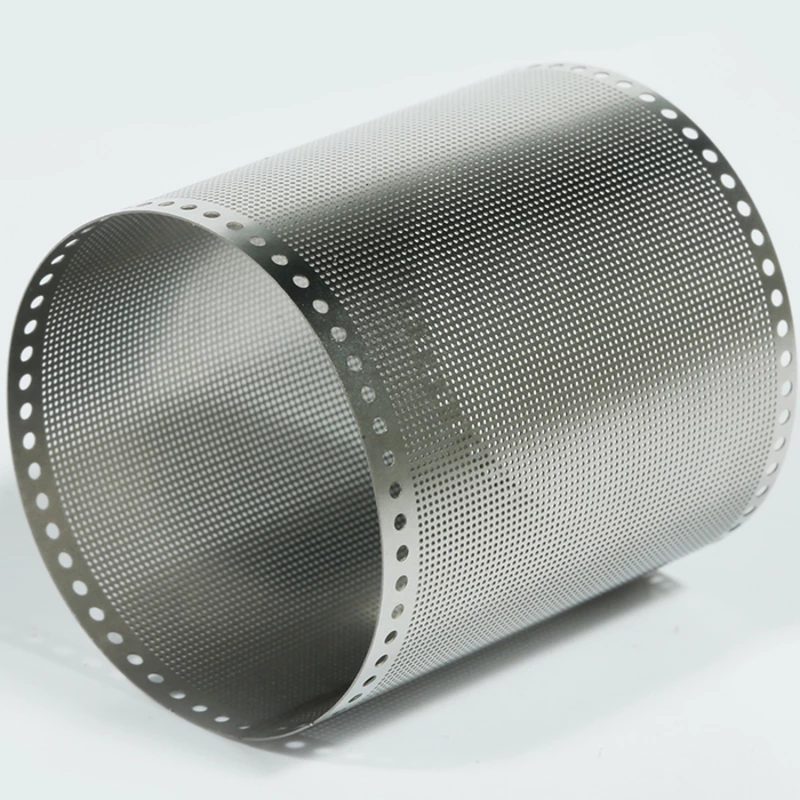

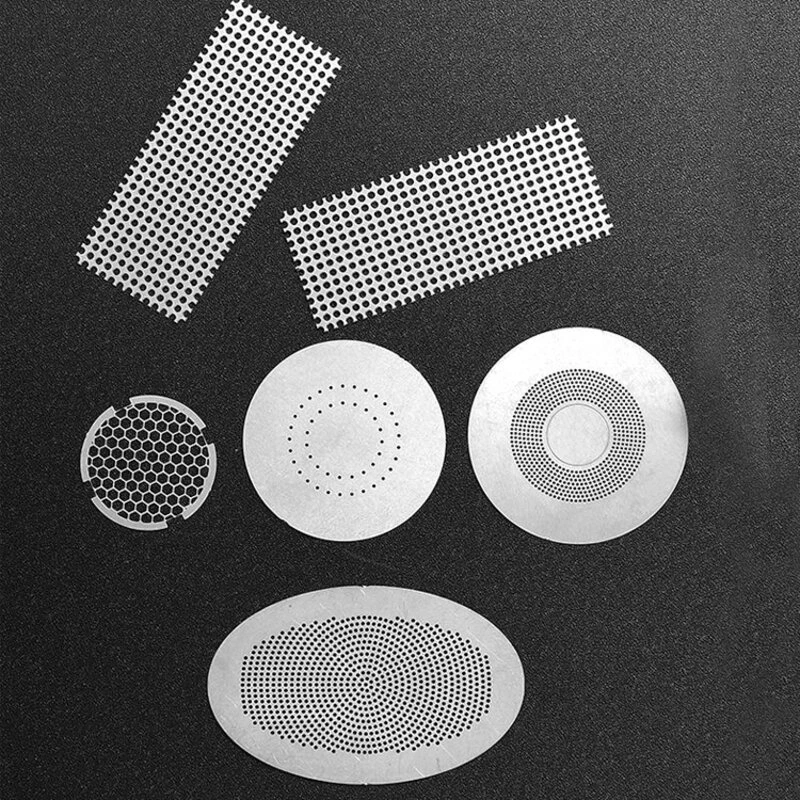

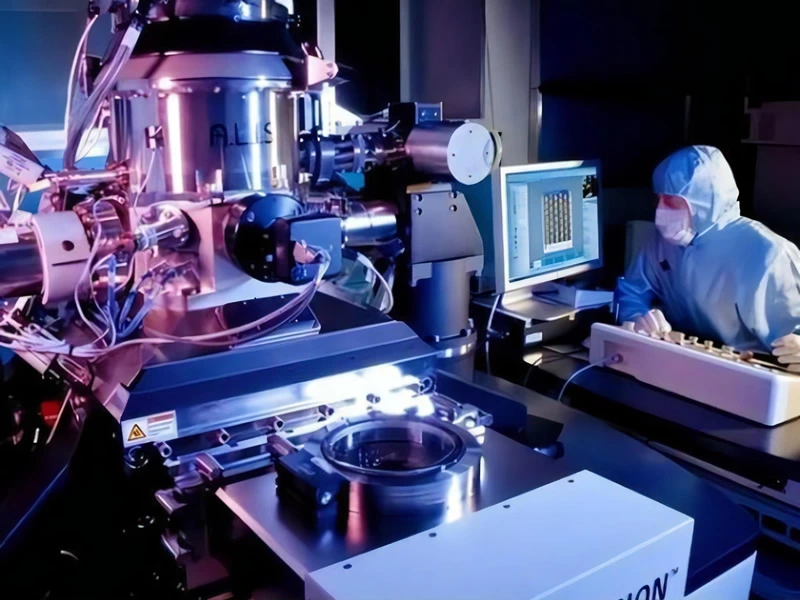

Etching service applications

Etching processes can create fine details, precise patterns, and complex designs on metal parts. For example:

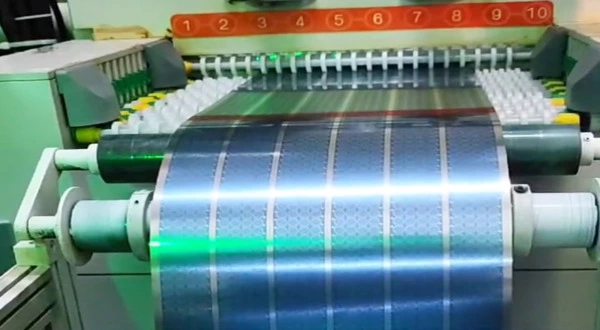

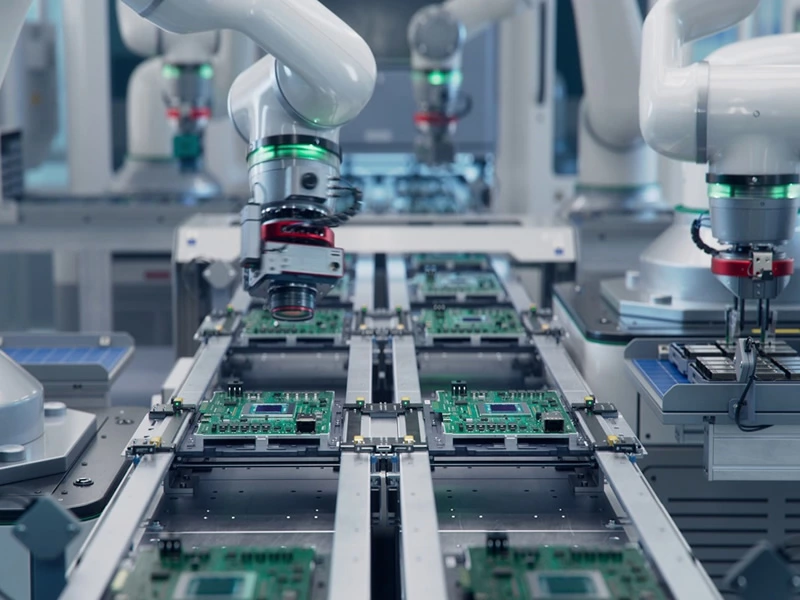

- Printed Circuit Board

- Electrical shielding

- connector

- Sensor cover

- Aerospace Instrument Panel

- Jewelry pattern

- Decorative nameplate

- Machine panel

- switch panel

- Calibration scale

- Medical device components

- Lock plate

- Antenna assembly

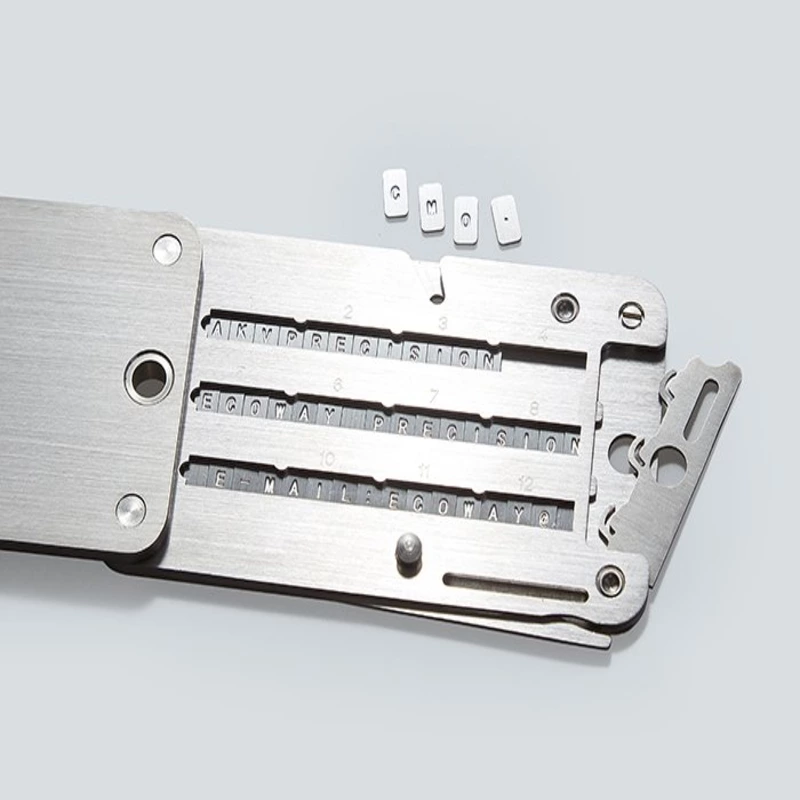

- Engraved Labels

- Architectural Panels

- microelectronic components

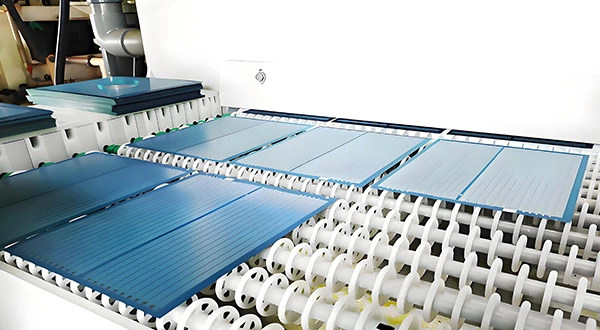

- solar panels

- control Panel

- Thin structural components

- Industrial signage

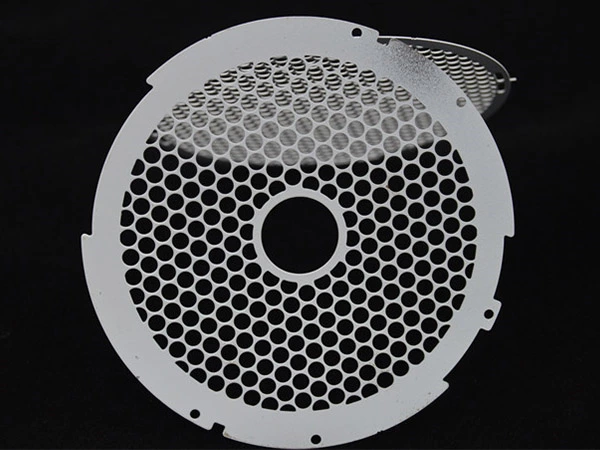

- heat sink

- Tool Templates

- PCB components

- Precision guide rail

- Measurement scale

- Miniature gears

- Electrical connectors

- Housing Coverage

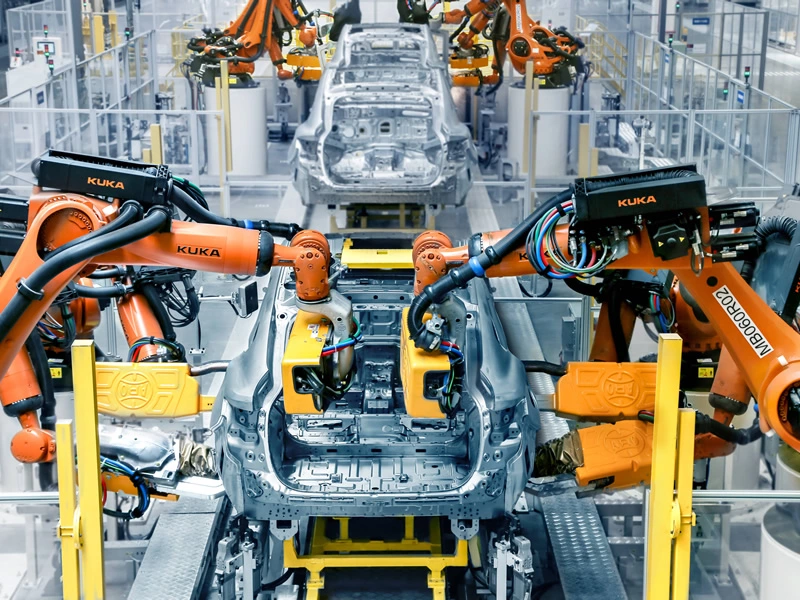

- Car dashboard

Jie Chen

buyer