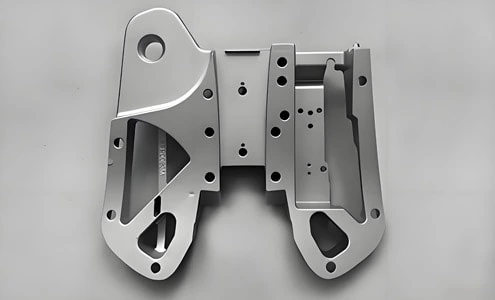

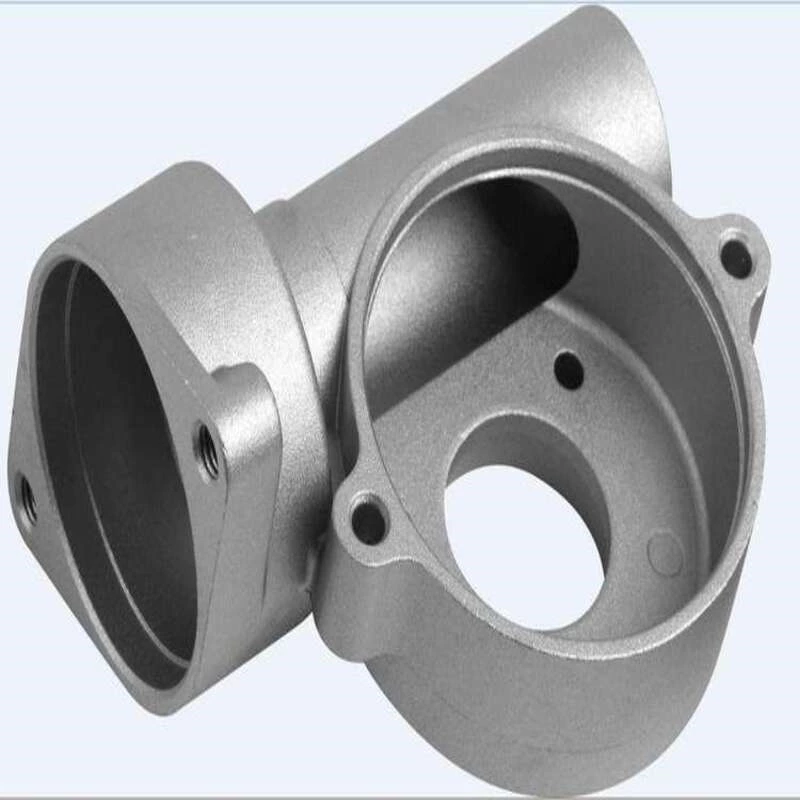

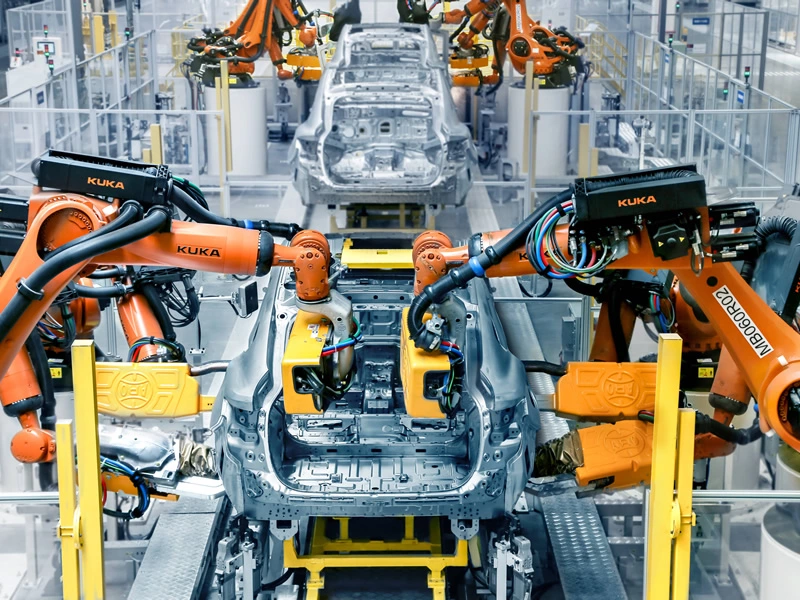

Lightweight, corrosion-resistant, and with a high strength-to-weight ratio. Used in the manufacture of complex thin-walled automotive parts, aircraft components, and electronic products.

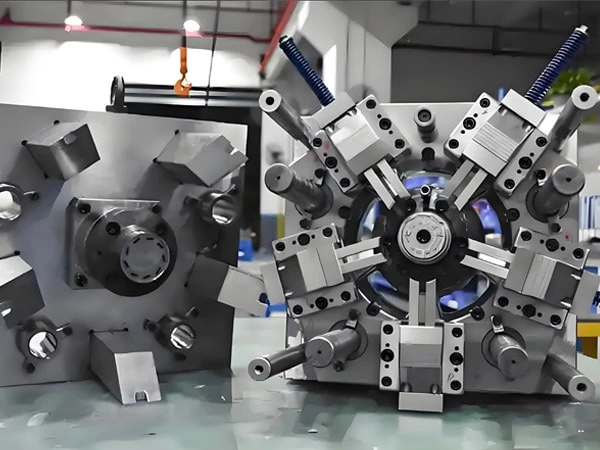

Processing technology: Aluminum alloy melting → High pressure die casting → Deburring → Finishing/Surface treatment

Materials: ADC12 (A383), A380, A360, ADC10 (A380), YL102, etc.

Features: Lightweight, high strength, corrosion resistant, excellent thermal and electrical conductivity

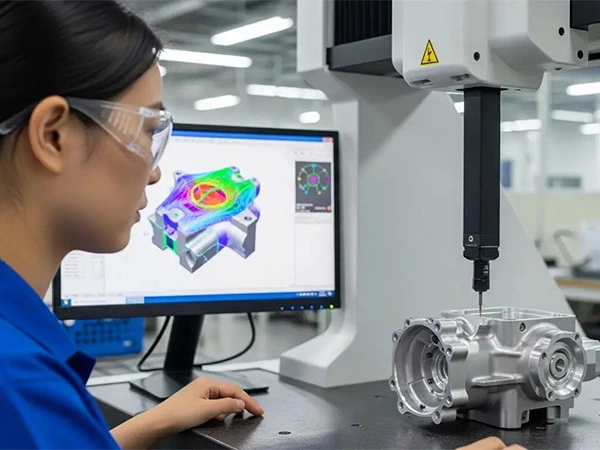

Tribute tea sizes: Small pieces (<50mm): ± 0.10~ ± 0.20mm; Medium pieces ( ± 50~ ± 200mm): 0.20~0.50mm; Large pieces (>200mm): ± 0.50~ ± 1.0mm

Geometric tolerances:

- Flatness: 0.1~0.5mm/10

- Coaxiality: 0.15~0.3mm

Maximum dimensions: Approximately 600 × 600 × 300 mm per piece (customizable)

Delivery time: Standard 20–30 days (including molds), negotiable for bulk orders.

Jie Chen

buyer