Why choose Tongyong Hardware MIM Manufacturing Services?

Simplify the procurement process for metal injection molding

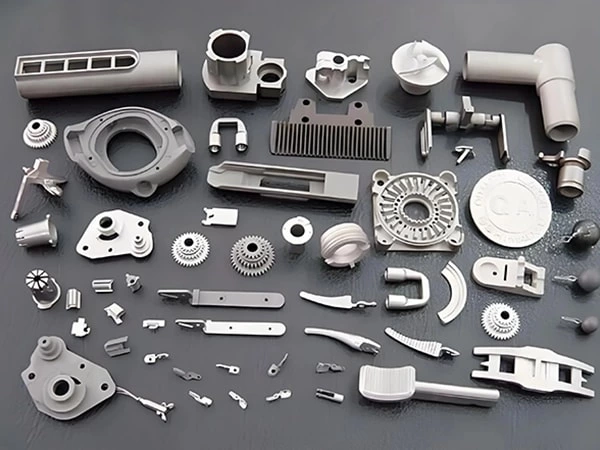

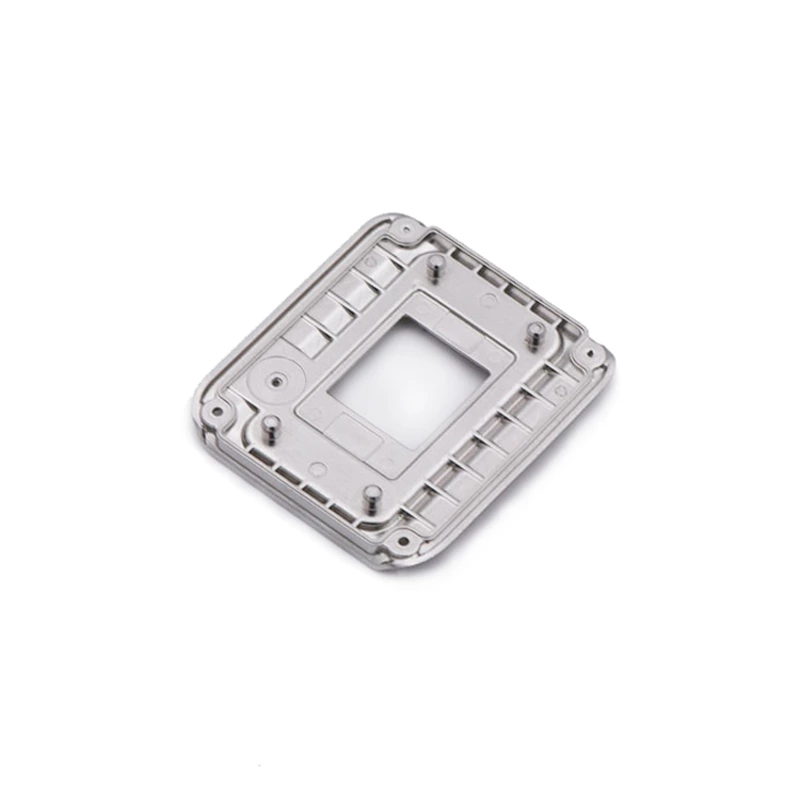

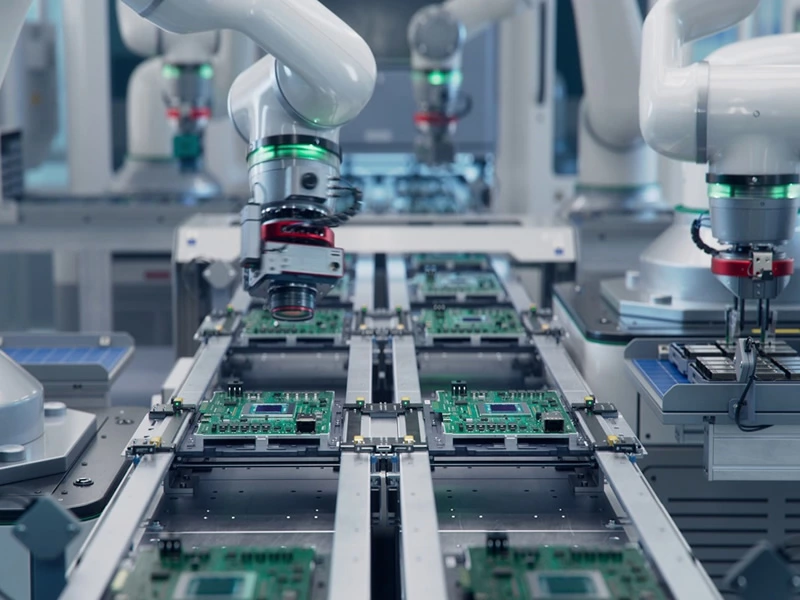

- Implementation of complex geometries

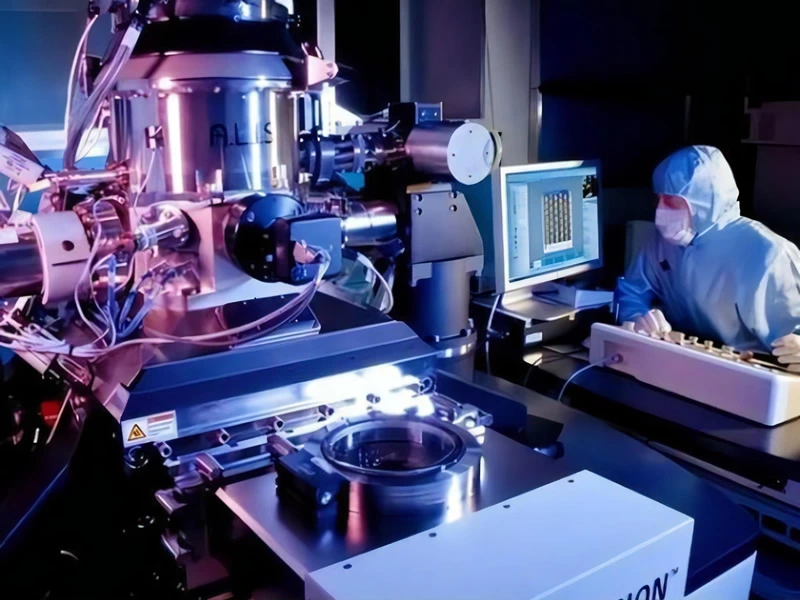

- Strict tolerances for small precision parts

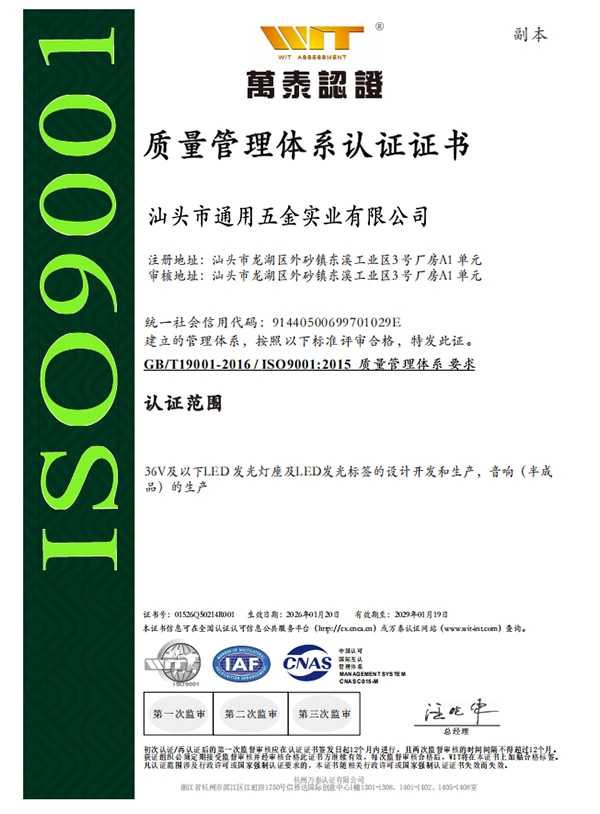

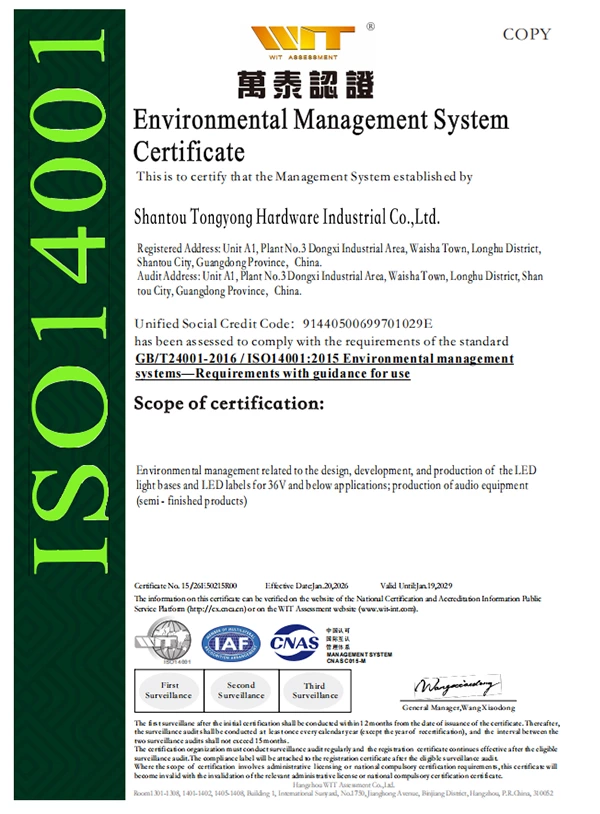

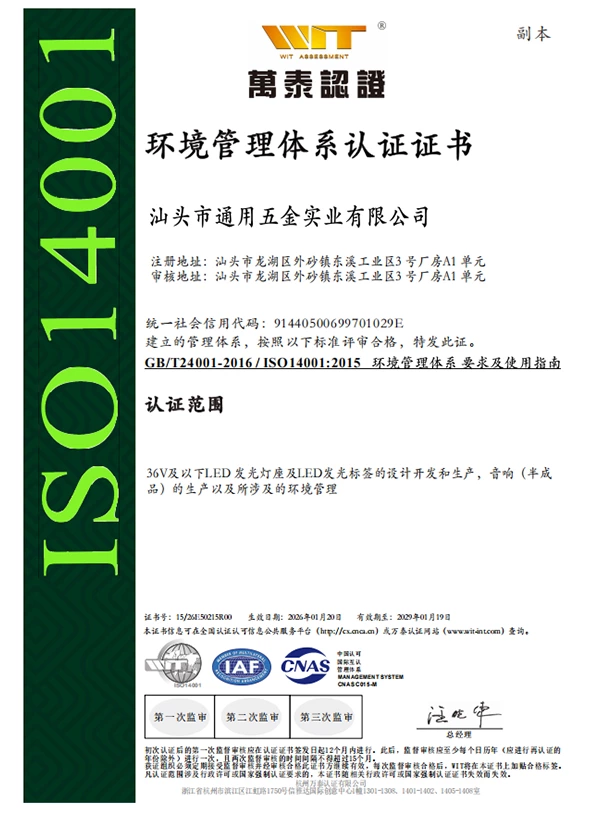

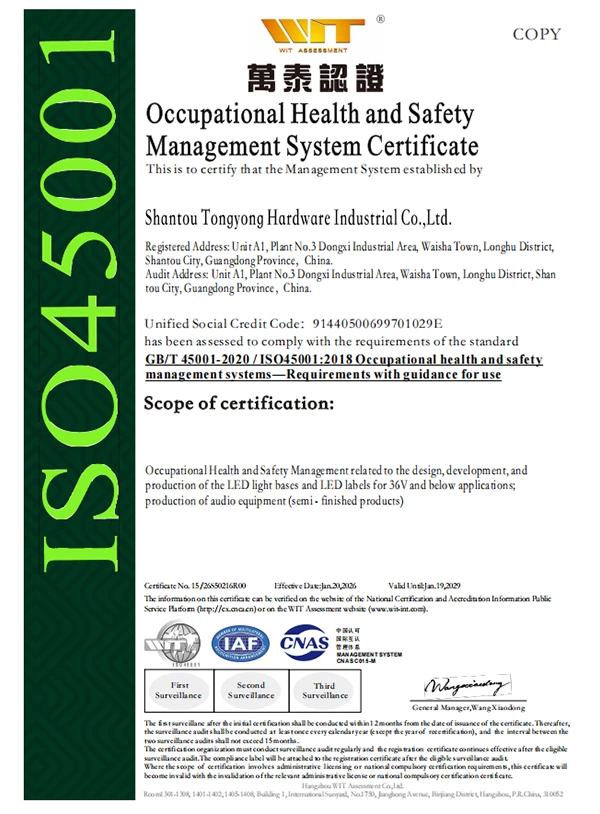

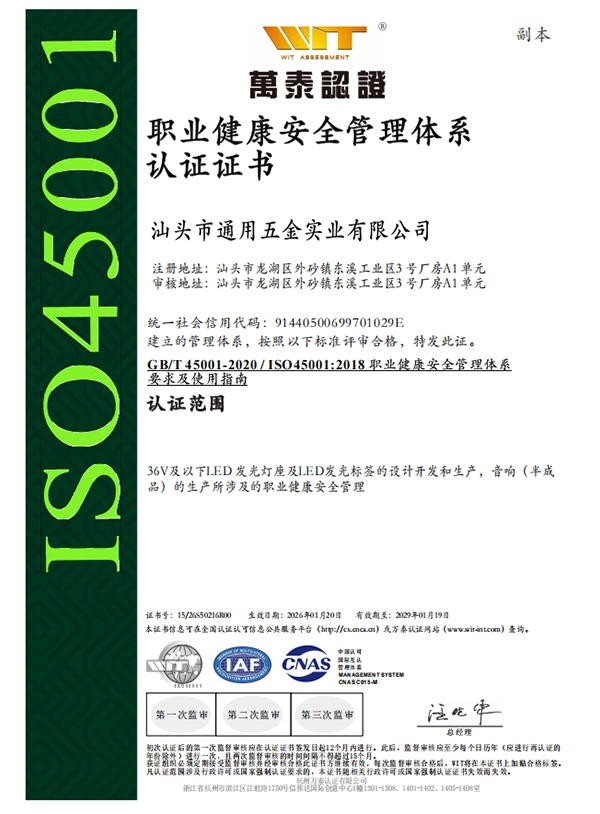

- Multiple certified metal materials

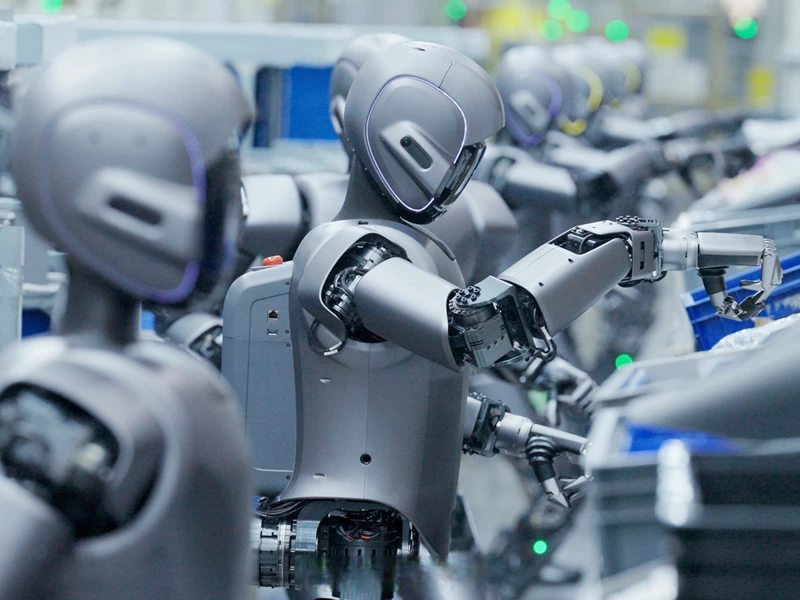

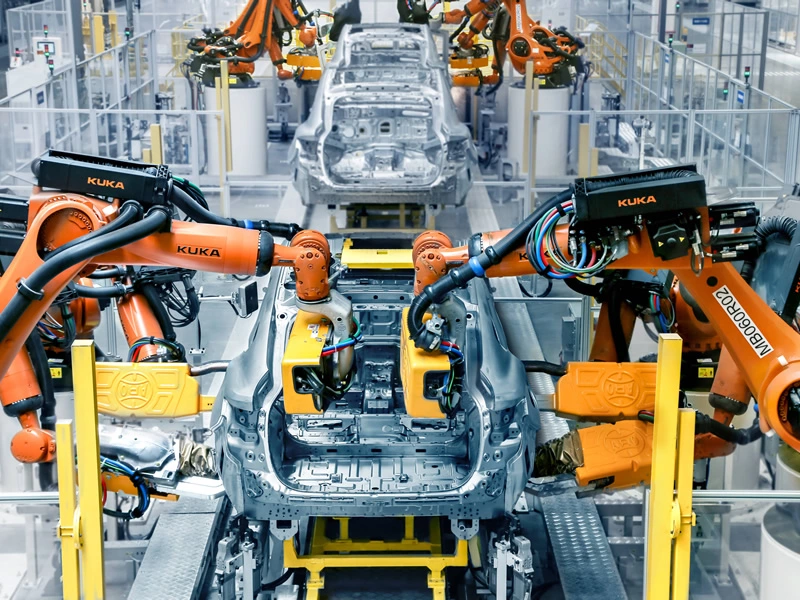

- Large-scale stable production

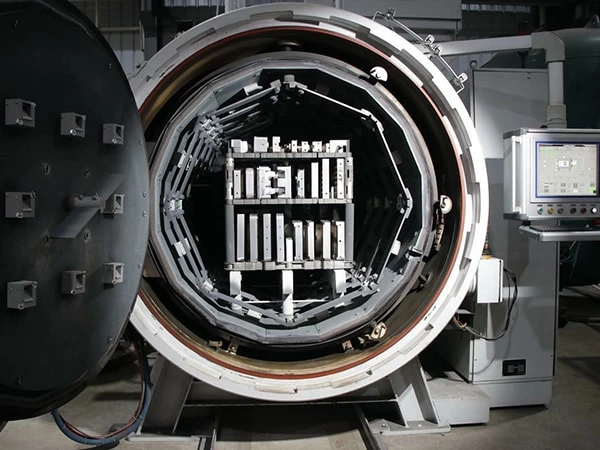

- Integrated degreasing and sintering control

- Uniform density and high mechanical strength

- Secondary processing and surface treatment options

- Suitable for micro and high-detail components

- Cost-effectiveness suitable for mass production

Jie Chen

buyer