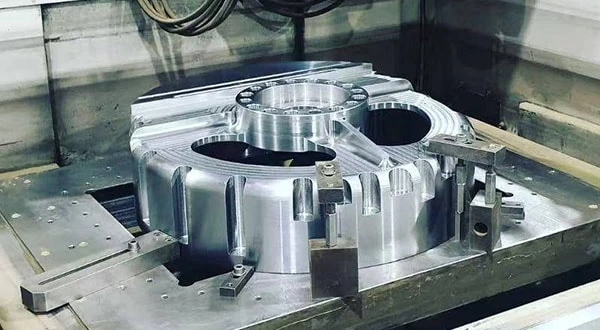

Uncompromising CNC machining quality

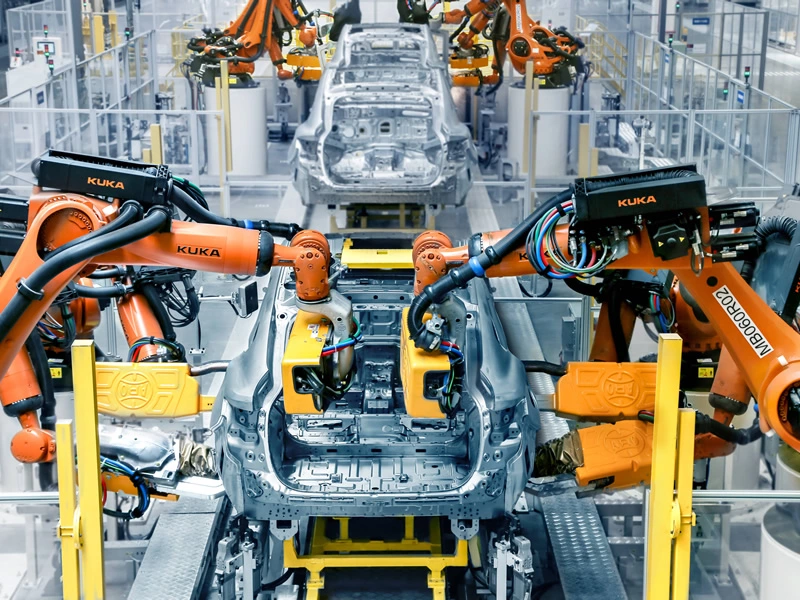

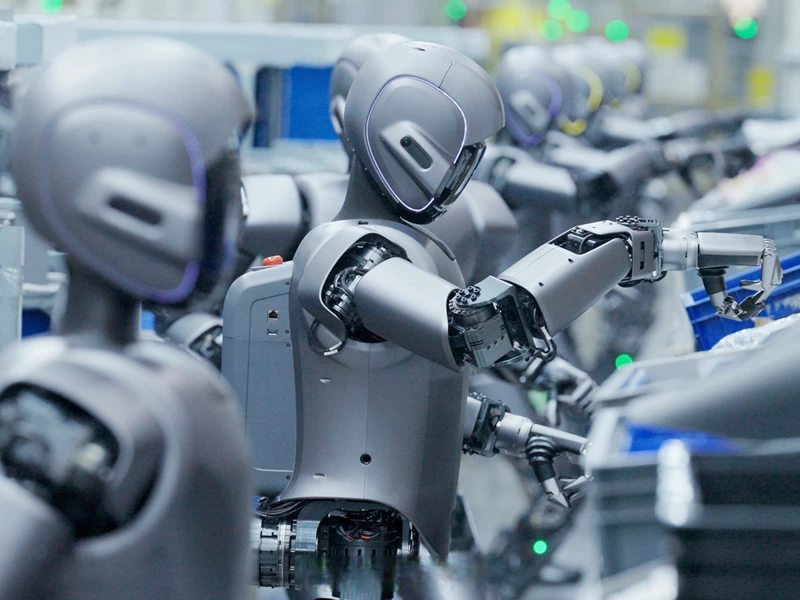

Your trusted partner for precision machining and rapid prototyping

- Services We support your processing projects through rapid communication and dedicated one-on-one project management.

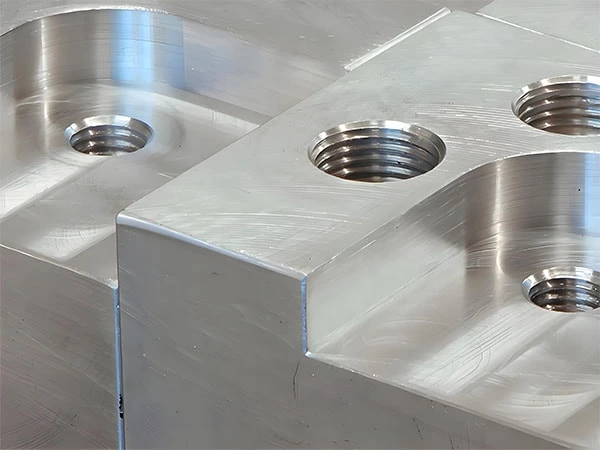

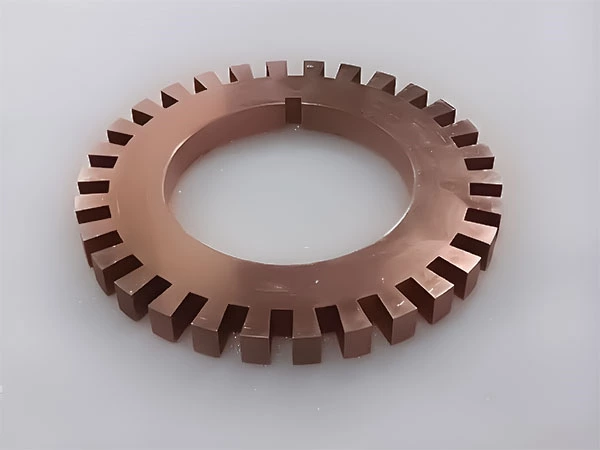

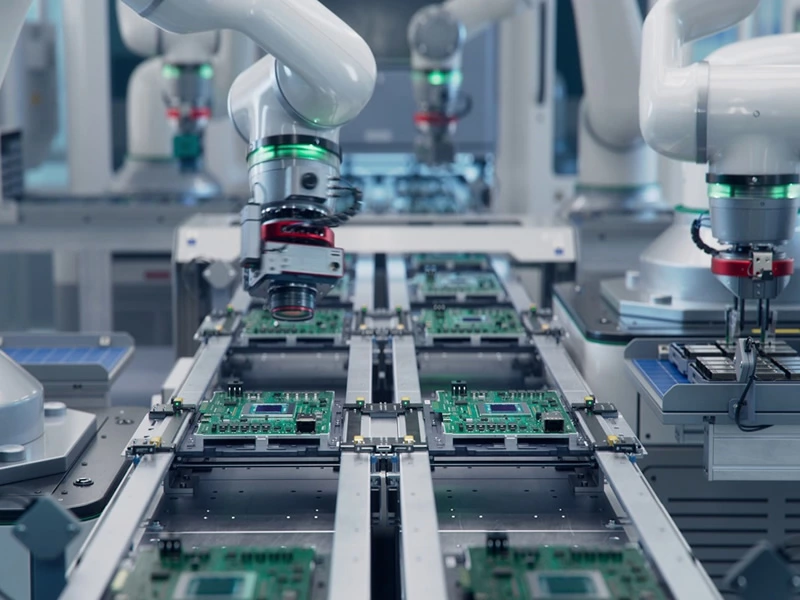

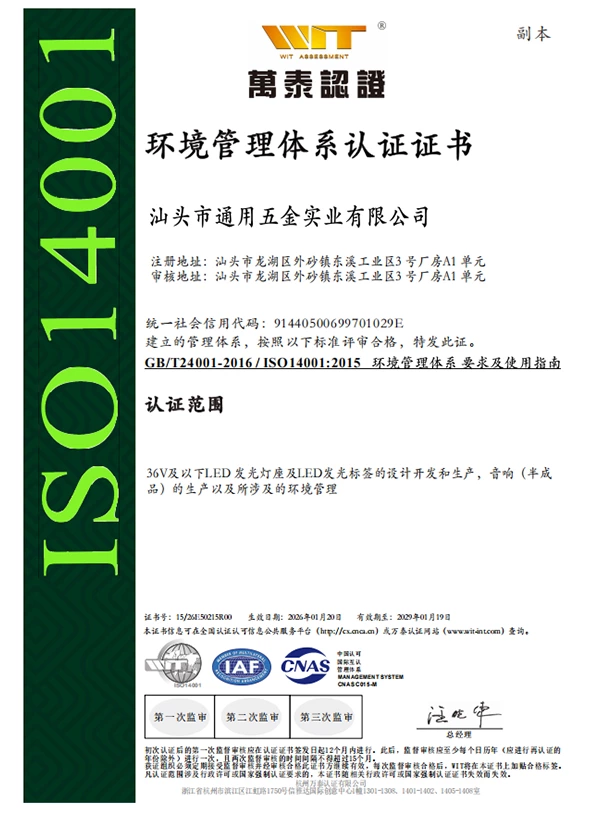

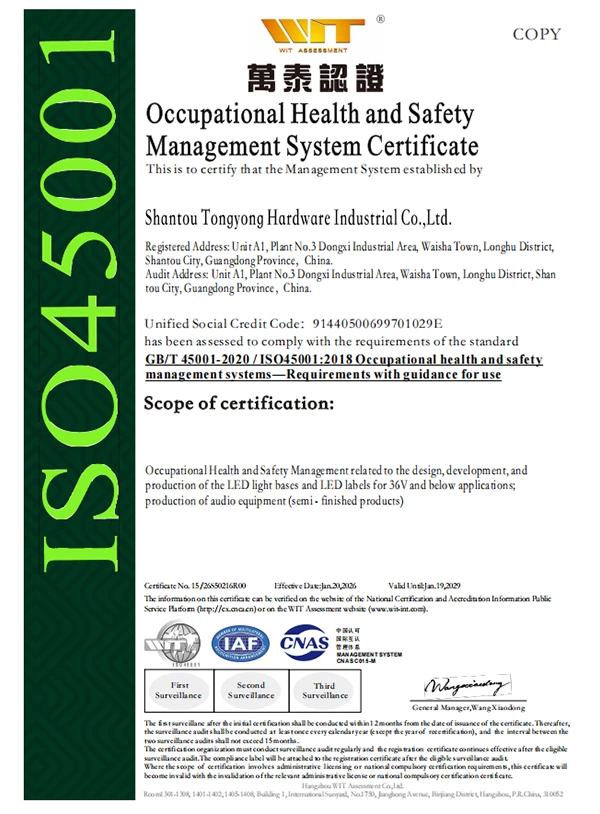

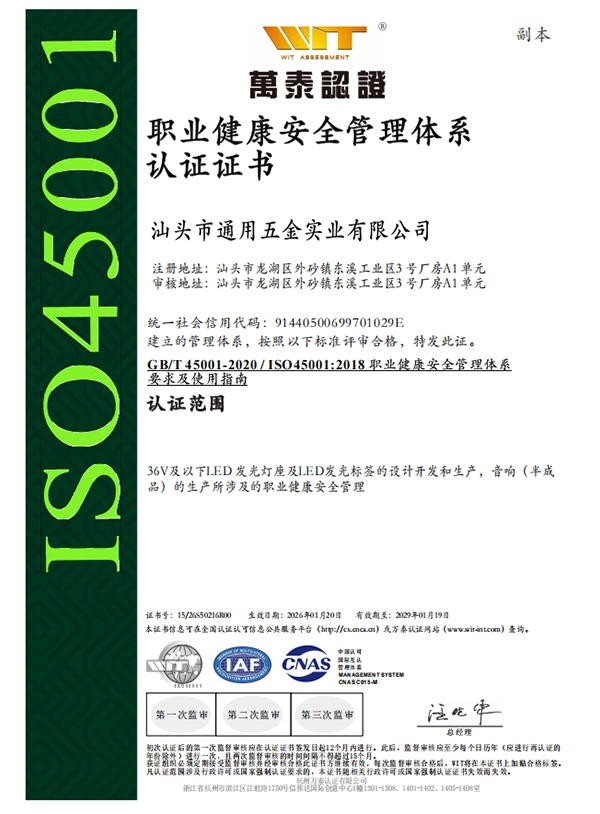

- Quality Each component is manufactured using certified materials and with strict process control to ensure consistent and reliable quality.

- Precision Our CNC systems maintain tight tolerances and provide consistent dimensional accuracy for complex, mission-critical parts.

- Speed With optimized workflows and flexible production capabilities, we are able to provide rapid processing, fast turnaround, and on-time delivery for orders of all sizes.

Jie Chen

buyer