At General Hardware, we efficiently advance each project through an integrated manufacturing process, from engineering confirmation to final delivery. From precision prototyping to mass production, our system maintains consistent quality while meeting stringent time requirements. Close collaboration between our engineering, machining, and quality teams ensures smooth process control, flexible scheduling, and reliable on-time delivery, helping our customers shorten lead times and maintain market competitiveness.

99%+

±0.01mm

1000000+

24/7

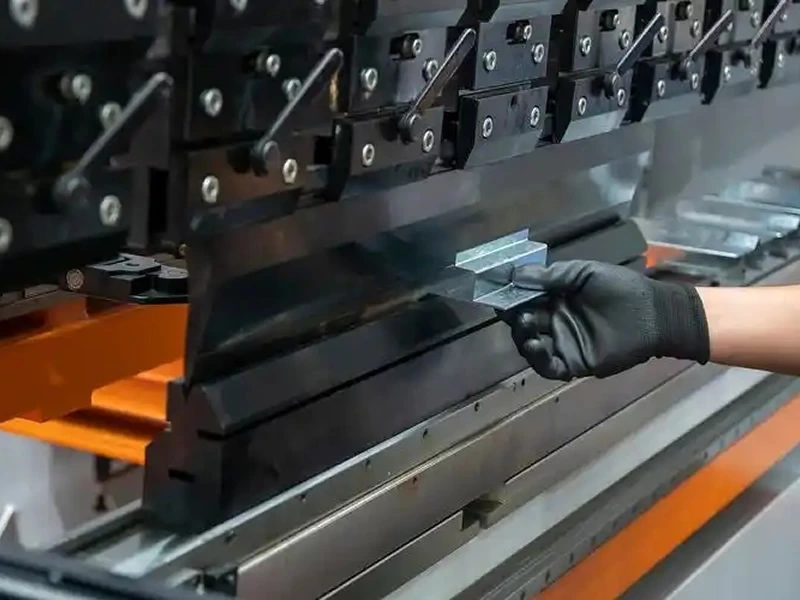

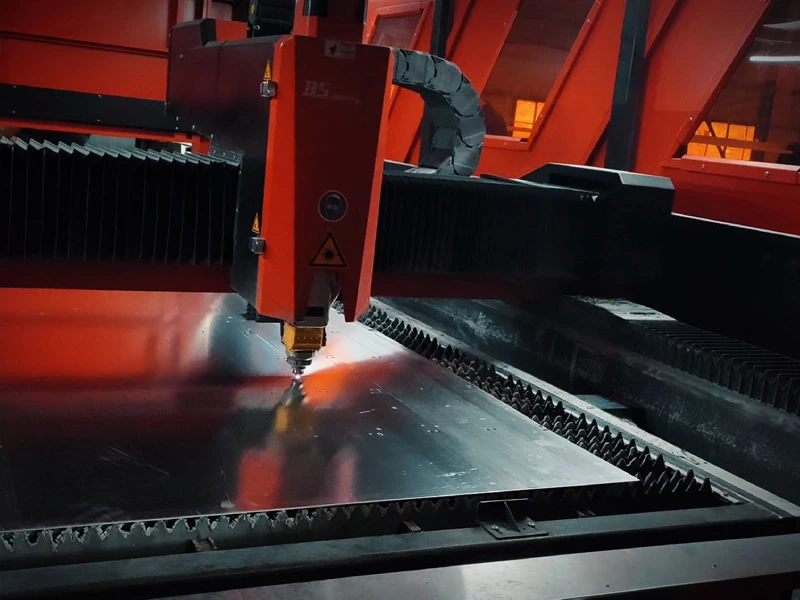

Our CNC machining, metal injection molding (MIM), sheet metal fabrication, die casting, extrusion, and etching processes are all managed within a unified manufacturing system. This integration reduces errors at handover points, improves process stability, and ensures consistency of results across different production methods. Furthermore, it facilitates a smooth transition from prototyping to mass production.

We rigorously control processing parameters, inspection standards, and material handling procedures throughout the entire production process. Each step is monitored to ensure dimensional accuracy, repeatability, and performance consistency. This approach provides reliable results for high-precision parts and mass production.

Our production schedule is optimized to efficiently handle prototyping, small-batch production, and large-volume orders. Flexible capacity allocation allows us to respond quickly to order changes and technical adjustments. Therefore, we are able to achieve rapid turnaround times while ensuring on-time delivery.

Quality begins with raw materials. All raw materials are carefully selected from qualified suppliers and inspected upon arrival to ensure they meet mechanical, dimensional, and performance requirements before being put into production.

Strict quality control is implemented throughout the entire production process. From machining and molding to surface treatment and assembly, each step follows standardized procedures and is monitored to ensure consistent product quality.

Before shipment, all components undergo a comprehensive final inspection to ensure they fully comply with the customer's drawings, specifications, and performance requirements.

For more information about our CNC machining services and custom metal parts, please contact us.

We use cookies to collect information about how you use this website. We use this information to optimize website functionality and improve our services. Learn more