Before we begin machining, we conduct a detailed consultation to fully understand your part requirements, tolerances, materials, and application scenarios. Our engineering team will ensure your project objectives are clear and feasible before putting you into production.

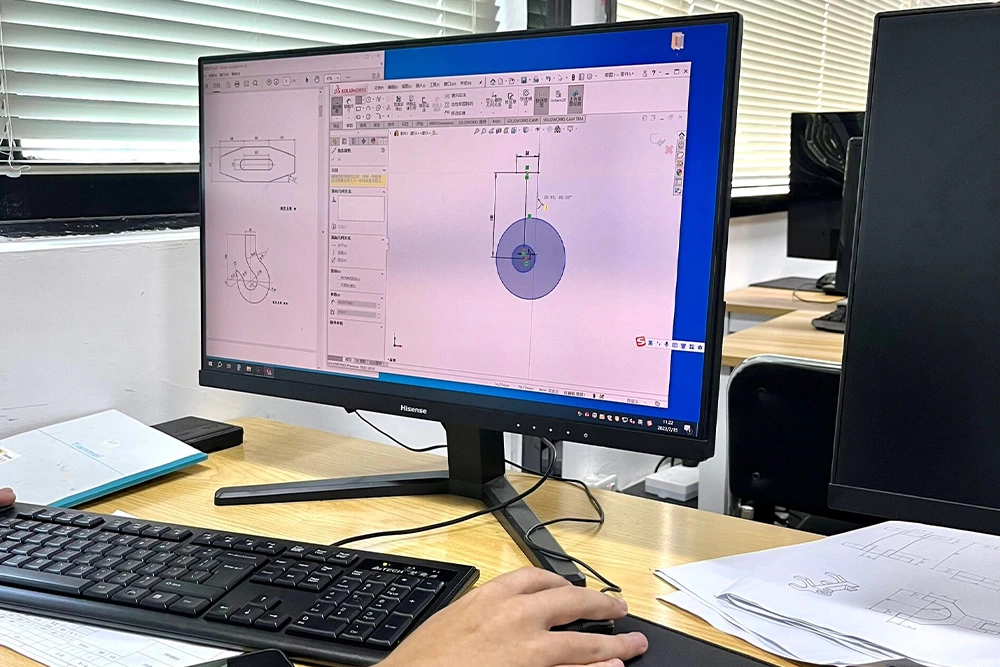

We will review your CAD drawings or samples to confirm all dimensions, features, and technical specifications. Our experts will assess manufacturability and, if necessary, suggest design optimizations to ensure cost-effective and precise production.

Before mass production, we will create CNC-machined samples or prototypes for your approval. This ensures that every detail, including dimensions, surface finish, and performance, meets your expectations before proceeding with production.

We use advanced CNC equipment to manufacture your parts with high precision and stability. Our processing techniques cover metals and engineering plastics, ensuring consistent quality for every order.

We offer a variety of surface treatment processes to enhance the appearance, durability, and functionality of your products. From polishing to anodizing, every step of the process can meet your product needs.

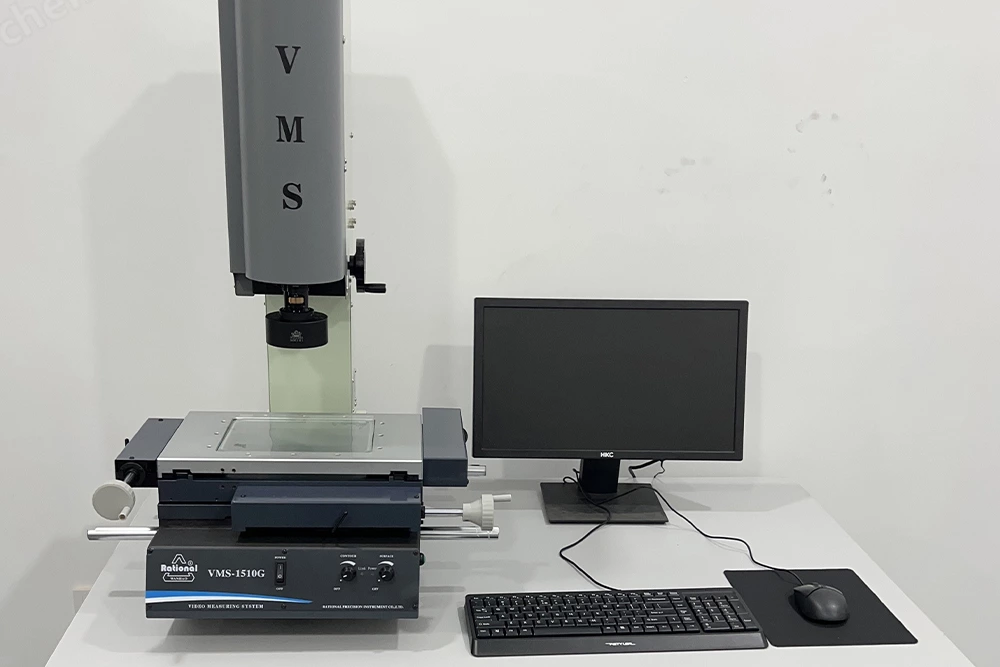

Each component undergoes a rigorous inspection process to ensure it meets required specifications. Our quality control team uses specialized measuring tools to guarantee accuracy and reliability.

Finished components are securely packaged with protective materials to prevent damage during transportation. We provide fast and reliable logistics solutions for customers both domestically and internationally.

Our support goes beyond delivery. We provide ongoing engineering support, redesign support, and production improvement suggestions to ensure your project runs smoothly.

For more information about our CNC machining services and custom metal parts, please contact us.

We use cookies to collect information about how you use this website. We use this information to optimize website functionality and improve our services. Learn more