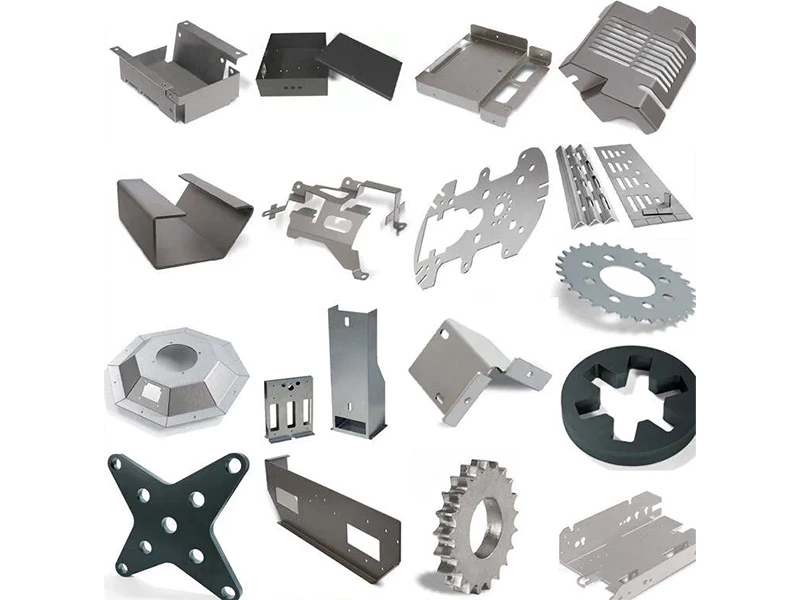

Sheet metal processing services

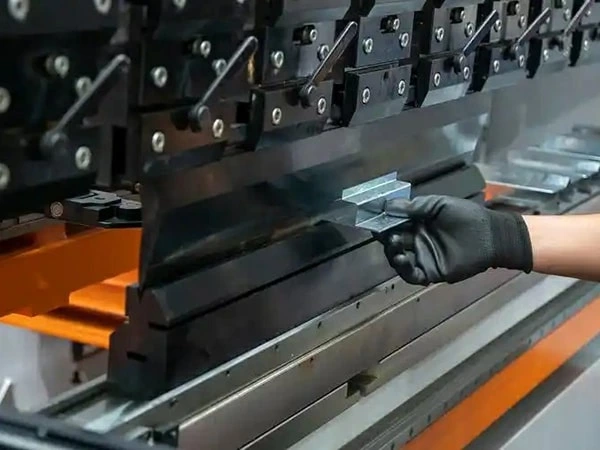

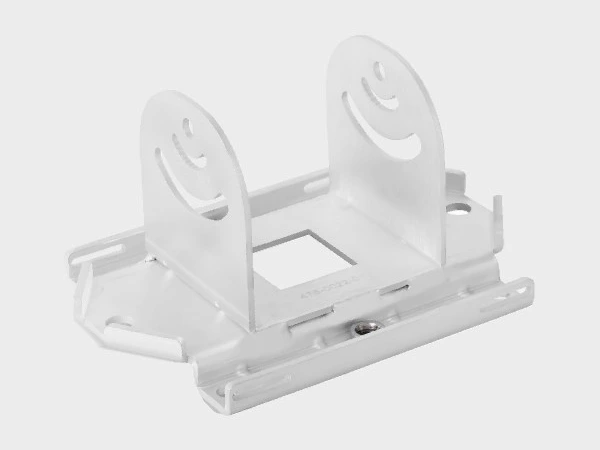

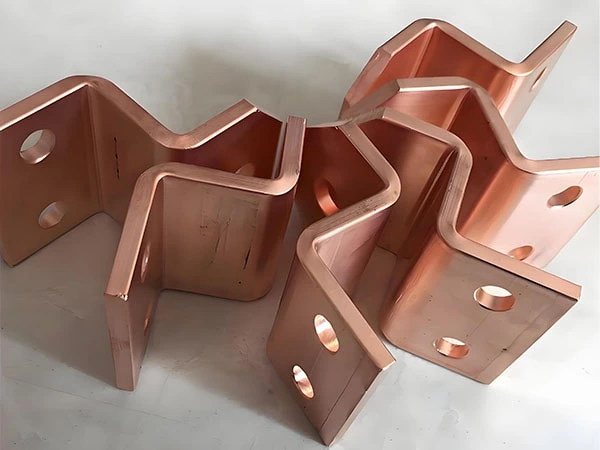

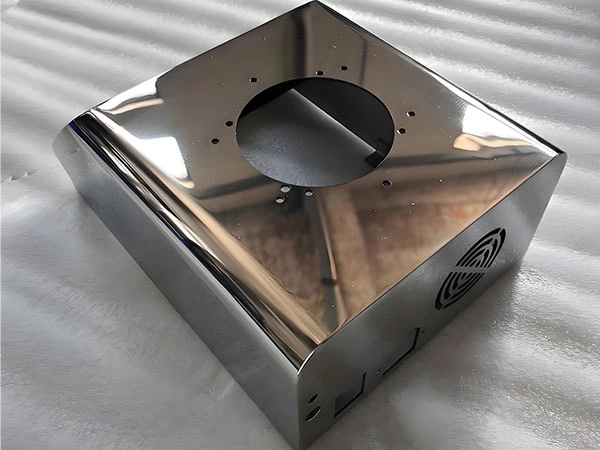

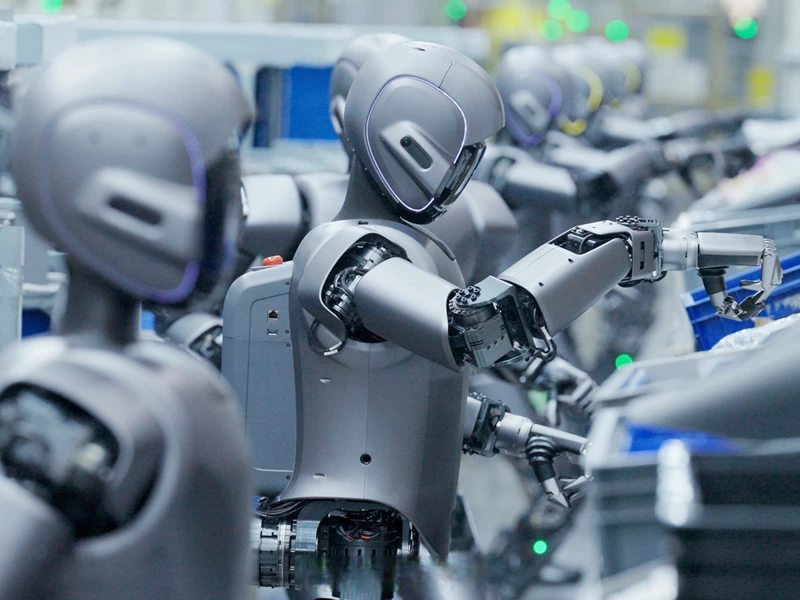

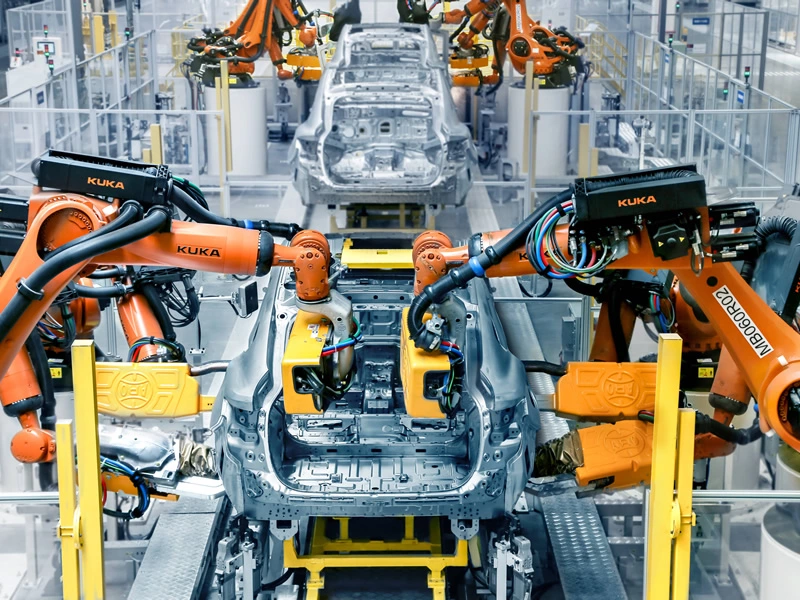

Reliable forming suitable for mass production of metal parts

- SERVICES We provide rapid response support and clear communication throughout the mold development and production process.

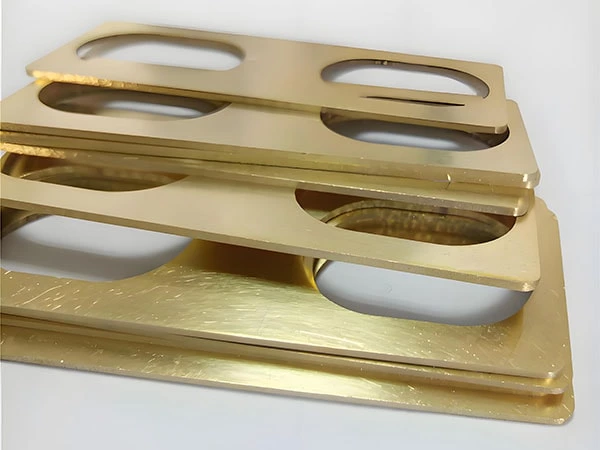

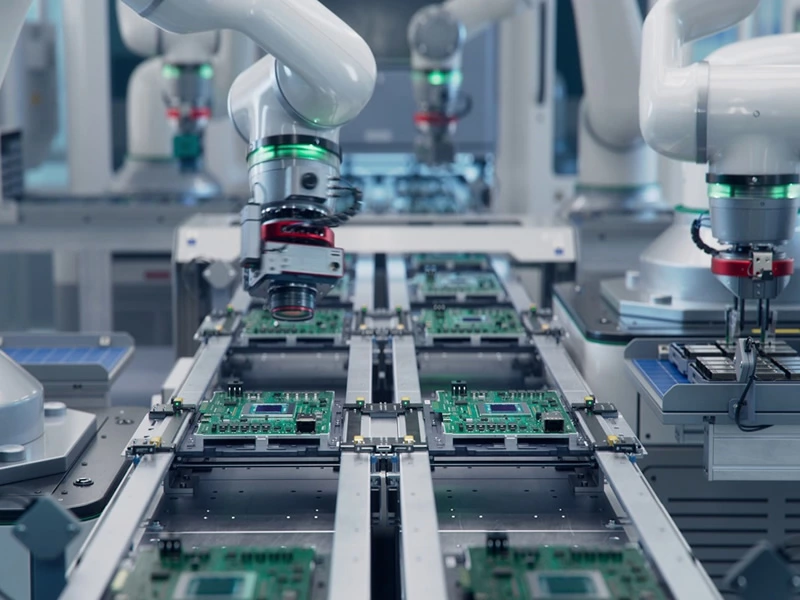

- High-quality stamped parts are produced under strictly controlled processes to ensure dimensional consistency and material performance stability.

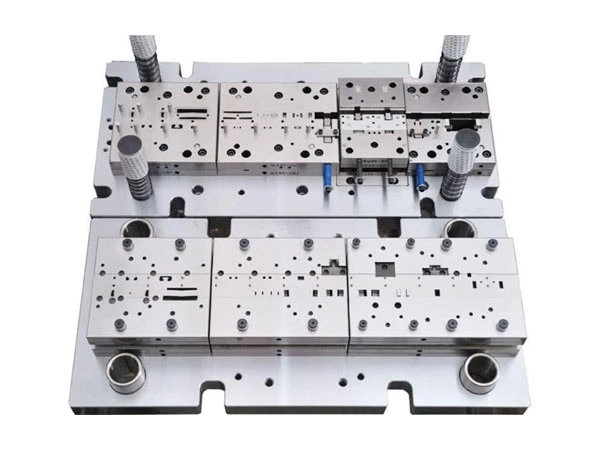

- Precision molds and standardized molding processes enable repeatable results for complex shapes and tight tolerances.

- Efficient tools and automated production lines enable rapid production and reliable delivery times for bulk orders.

Jie Chen

buyer