Tongyong Hardware announced a major upgrade to its high-precision CNC manufacturing platform.

A new stage of technological progress

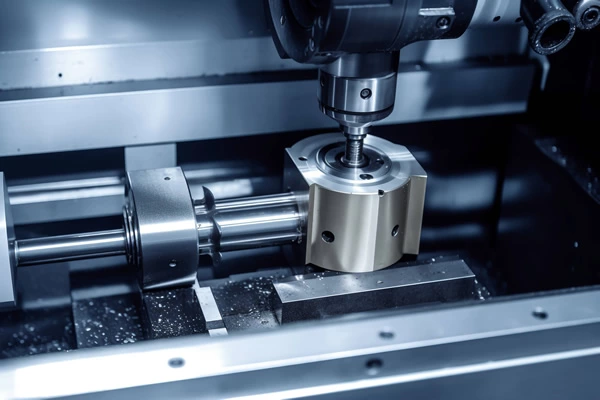

Shantou Tongyong Hardware Industry Co., Ltd., a leading enterprise in China's precision machining industry, announced a major upgrade to its integrated CNC machining platform. Adhering to the long-term philosophy of "high starting point, high efficiency, and high quality," the company continuously expands its technological capabilities to meet the evolving needs of global customers in the fields of electronics, medical devices, industrial equipment, consumer goods, and mechanical assembly.

Integrated multi-process manufacturing system

The core of this upgrade lies in expanding the company's multi-process manufacturing system, which integrates CNC milling, CNC turning, metal processing, metal injection molding (MIM) parts production, spring etching, and fastener manufacturing. By integrating these capabilities into a unified workflow, Tongyong ensures consistent quality control, shorter lead times, and higher repeatability across various projects, from rapid prototyping to mass production.

Enhanced material and tolerance capabilities

The newly launched machining platform supports the machining of a variety of advanced metals, including stainless steel, carbon steel, aluminum alloys, brass, and titanium, as well as high-performance polymers such as PEEK, ULTEM, PPSU, and engineering plastics. Precision tolerance control up to ±0.0025 mm ensures it meets the demands of rigorous applications such as robotics, optics, medical device housings, and sensor assemblies.

Upgraded quality assurance system

Quality assurance remains at the heart of Tongyong's technology roadmap. This upgrade includes a wider deployment of coordinate measuring systems, microscopes, automated inspection equipment, and in-machine probes. Combined with statistical process control, these tools ensure that every part fully meets customer specifications.

Strengthen engineering collaboration

The company's R&D team has also enhanced its collaborative engineering services. Early DFM feedback, tolerance optimization, and materials consulting help customers accelerate development cycles while reducing manufacturing costs.

Supporting the future development of the high-precision industry

With the development of industrial automation and product miniaturization, Tongyong's upgraded platform makes the company a reliable partner for industries that require precision, stability, and fast turnaround time.

Committed to long-term innovation

Looking ahead, the company is committed to further modernizing equipment, developing smart factories, and deepening integration with customer R&D. These upgrades will solidify Tongyong's position as a competitive manufacturing partner, providing it with high-quality CNC machining solutions.