Tongyong Hardware expands its global CNC machining services by enhancing its processing capabilities.

Enhance global competitiveness

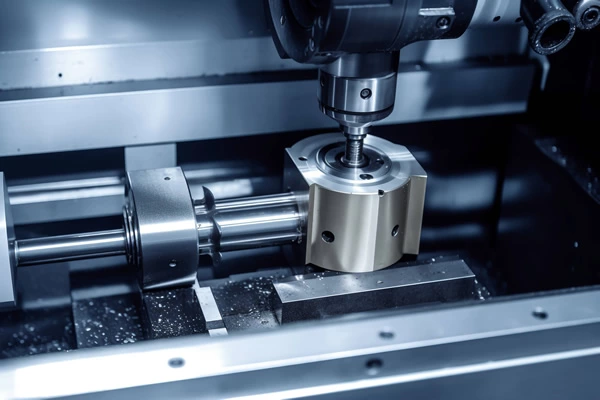

Shantou Tongyong Hardware Industry Co., Ltd., renowned for its strong production capacity and reliable service, recently announced the expansion of its CNC machining and hardware manufacturing platform. The company aims to provide customers with a smoother and more efficient manufacturing experience.

Integrated production capabilities

The latest upgrade integrates CNC milling, CNC turning, metal processing, metal injection molding (MIM) processes, spring etching, and fastener production. Customers can enjoy one-stop service, simplifying complex manufacturing processes and reducing management costs.

Customer-centric workflow

From initial communication to DFM optimization, Tongyong ensures clients receive timely engineering guidance, thereby reducing risk and processing costs. Its flexible service model supports industries such as electronics, home appliances, medical, automotive, automation, toys, and industrial equipment.

Stable quality and reliable testing

With upgraded testing equipment and experienced quality engineers, Tongyong conducts rigorous verification for every project. Surface finish, tolerances, and material certifications are carefully controlled to ensure high repeatability.

Faster delivery cycles and production efficiency

Improved workflow management and operator training enable the company to shorten delivery cycles for prototyping and mass production, thereby enhancing the security of the customer's supply chain.

Service-oriented business philosophy

Flexible order sizes, rapid response, customized packaging, and comprehensive after-sales support reflect Tongyong's customer-first philosophy. This approach helps build long-term international partnerships.

Towards Future Growth

As global demand for precision components continues to grow, Tongyong continues to invest in innovation, capacity expansion, and operational upgrades to better serve its global customers.