Tongyong Hardware provides high-precision CNC components for European medical device projects.

Customer's urgent challenges

A European medical device manufacturer has placed an emergency order with GE for several high-precision metal and PEEK components for a diagnostic instrument that is scheduled to be tested within two months.

Engineering assessment and DFM optimization

Tongyong Hardware's engineering team conducted a comprehensive DFM review, adjusting tolerances, materials, and processing sequences to improve manufacturability without compromising functionality.

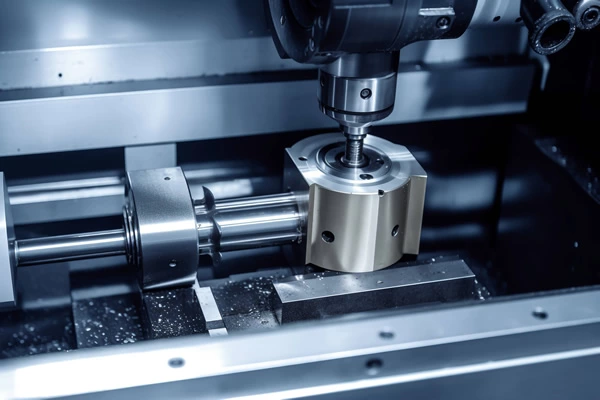

Precision machining of medical-grade components

Tongyong Hardware utilizes CNC milling and turning technologies to overcome challenges such as microgrooving, tight shaft tolerances, and the flatness requirements necessary for the equipment's optical alignment system.

Rapid prototyping and transparent communication

Throughout the process, Tongyong Hardware provides real-time progress updates, inspection reports, and sample verification, enabling customers to make quick decisions and maintain a rigorous development schedule.

Seamless transition to mass production

After the prototype was successfully approved, Tongyong Hardware quickly began small-batch production while maintaining consistent precision across all products.

Client approval and project impact

The client praised Tongyong Hardware for reducing project risk, accelerating development, and delivering perfectly compliant components.

A broader impact on the high-precision industry

This case highlights Tongyong Hardware's ability to support demanding industries such as medical, aerospace, robotics, automation, and smart electronics.